Aquapolo: Customer Story Key Figures

15% greater operational efficiency

Lower cost of ownership

Drinking water secured for >500,000 residents

Brazil’s largest wastewater treatment plant uses EcoStruxure to increase operational efficiencies: for every litre of recycled water they produce, a litre of drinking water is saved.

The Challenge

Aquapolo needed to:

- Address a severe shortage of potable water for the local community

- Meet the increasing demand for water for industrial use

- Manage 20 different KPIs related to water quality and quantity

- Reduce production costs

- Improve operational efficiency

The Solution

Apps, Analytics and Services: EcoStruxure Augmented Operator Advisor, AVEVA Manufacturing Execution System*, AVEVA Historian*, expert services

Edge Control: Modicon M238 and M340 PLCs, AVEVA Plant SCADA*

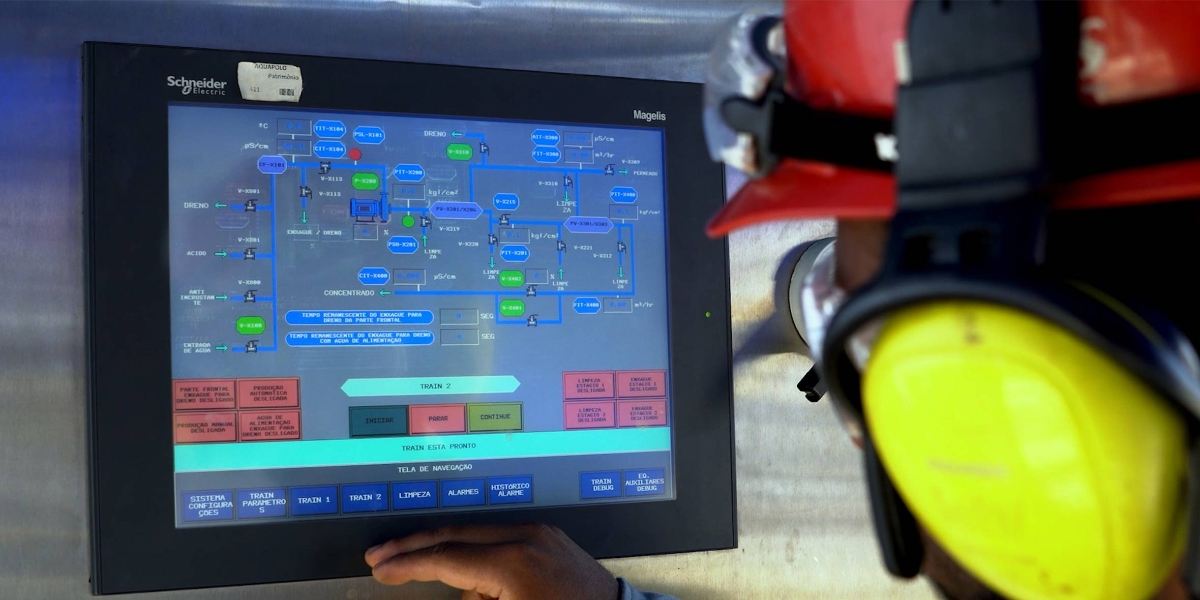

Connected Products: Harmony HMI, Foxboro instrumentation, ConneXium switches

- AVEVA Plant SCADA and AVEVA Historian control and capture information on 20 qualitative and quantitative parameters.

- Foxboro sensors ensure accuracy of the readings around effluent entry into the reverse osmosis/ultra-filtration plant and send the information to the Modicon PLCs, which control the industrial water treatment, pumping stations, and reservoir operations.

- Operators monitor the process locally via the Harmony HMI.

- AVEVA Manufacturing Execution System supports invoice calculation.

The Results

By implementing a full EcoStruxure for Water and Wastewater solution, including leading-edge industrial software from AVEVA, Aquapolo realised:

- 15% reduction in total production costs and improved efficiency

- Improved quality control with real-time analysis of water quality

- Real-time dynamic billing system

- Better regulatory compliance to protect the environment

- Capacity to deliver potable water for more than 500,000 residents

Sheila de Oliveira, Production Manager, Aquapolo

Customer Testimonial

“Schneider’s EcoStruxure platform provided us with an increase of up to 15% in the plant’s total operational efficiency.”

Learn more

Access more customer stories

Don’t stop here. We’ve got lots of success stories to browse through.

Read moreDiscover EcoStruxure

Learn how your business can achieve success too.

Explore moreInnovation Summits

See highlights from recent Innovation Summits and find out about the next event.

Find out more

Aquapolo, Brazil's largest wastewater treatment plant, partnered with Schneider Electric to address the growing demand for water for industrial use while reducing operating costs and increasing efficiency. The EcoStruxure for Water and Wastewater solution, including leading-edge industrial software from AVEVA, also helped it to improve its regulatory compliance, increasing its industrial sustainability.