Discover Altivar Process ATV900

Discover Altivar Process ATV900

About Altivar Process ATV900

The next generation of variable speed drives, Altivar Process is designed to deliver IIoT benefits. A smart, connected EcoStruxure-ready Drive with built-in intelligence to gather data and share information to the enterprise level, the Altivar Process can improve operational efficiency, profitability and reduce total cost of ownership (TCO). As the only range on the market providing a common platform from 0.75 kW to 2600 kW in all voltages, Altivar Process is easy-to-use with a consistent experience for usability, functionality, and performance, and the added value of peace of mind and flexibility delivered through Drives Services. Designed to assist OEMs, system integrators, and industrial process owners, Altivar Process drives improve process performance by enabling full information and operational technology convergence.

Benefits of Altivar Process ATV900

Benefits of Altivar Process ATV900

Process optimisation

Bring intelligence to your system by enabling your assets to provide advanced process data for smarter operations.

Enhance equipment effectiveness

Improve your productivity and availability by up to 20%.

Energy management

Optimise and reduce your energy consumption by up to 30%.

Asset management

Enhance your asset management by 20% and reduce downtime with smart maintenance.

We have the offers for you

Altivar Process ATV900

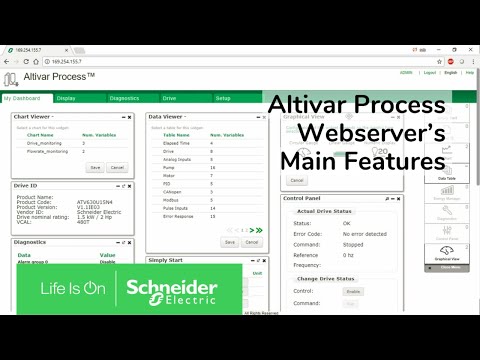

ATV900 Drives focuses on maximum productivity with exceptional motor control and connectivity. For cabinets, Altivar Process drives are available in wall-mounting and floor-standing integrated solutions. These Process drives provide a wide range of integrated functions, such as: • Safety and automation functions for the most demanding applications. • Various optional fieldbus modules are available for seamless integration into the main automation architectures. • I/O standard facilitates adaptation of specific applications. • Intuitive commissioning through graphic display terminal. • Embedded web server for remote monitoring and control access. • Integrated harmonic filters help in the protection of grids and save energy. • Installation of EMC conformity through integrated EMC filters.

Wall Mounting

Altivar process Wall-mounted is a ready-to-use Drive for easy integration inside an enclosure or directly on a wall in an electrical room. It is available in different protection degrees and a wide range of voltages and power. • IP20 and 21/UL Type 1 from 0.75 kW to 315 kW/1 HP to 500 HP at 380...480 V. • IP20 and 21/UL Type 1 from 2.2 to 90 kW/3 to 125 HP at a 500...690 V. • IP55 from 0.75 to 90 kW/1 HP to 125 HP at 380...480 V.

Floor standing

The Altivar Process Floor-Standing Drive IP21/IP54 is a compact and efficient solution. It combines power and control modules, semiconductor protection fuses, line chokes, and a filter to protect the motor. Accessible busbars simplify the motor and power wiring. The IP54 variant includes a main switch and a system to separate cooling airflow for better performance in polluted environments and managing thermal stress in plant rooms.

Driving sustainability forward with Altivar Variable Speed Drives

Improve energy efficiency and sustainability with Altivar variable speed drives. Manage motor control applications up to 20 MW with products ranging from compact products to custom-engineered solutions.

Altivar Process Drives | Advanced Functions Reliability for MMM&

Drive sustainable industrial operations with Altivar Process Drives from 0.75 kW to 2600 kW in Low Voltage and up to 20MW in Medium Voltage.

Altivar Process ATV900 Variable Speed Drive

Altivar Process ATV900 Drives with advanced functions for segments such as Mining, Metals, Oil, Gas, Food, Beverage and Hoisting from 0.75 kW to 2600kW

Maximise the performance with ACVC

ACVC (Adaptive Cascade Vector Control) is the New Motor Control, a revolutionary improvement in the last decades in the motor control industry.

How-to videos

How-to videos

Getting started with Altivar Process ATV900

Using the webserver

Setting a maintenance event

Setting the ramps switching

Features

Features

• Power range : 0.75 kW to 2600 kW• Voltage range : 200 – 400 – 690 V Three-phase• Motor type : Induction, PM, Reluctance, IE2-IE3-IE4 motors• Motor control type : Open and closed-loop• THDI : THDi 48%(Embedded), THDi 10% or THDi 5% with Passive filter or multi-pulse supply, THDi = 3% with Low Harmonic module<<<< • Safety : STO - SS1, SS2, SOS, SLS, SMS, SBC, SDI (SIL3 Ple)

• Master-slave load sharing • Hoisting management • High accuracy torque control • Embedded dual-port ethernet • Advanced safety • WebServer — DHCP with native EtherNet • Adaptive Cascade Vector Control - ACVC • Fast Device Replacement • Energy monitoring with current sensor • Achilles L2 cyber-security • High-speed hoisting • Brake logic control • Rope slack handling • DC injection for fast stop • IGBT monitoring

• STO: Safe Torque Off • SLS: Safely Limited Speed • SS1: Safe Stop 1 • SMS: Safe Maximum Speed • SBC: Safe Brake Control • GDL: Guard Door Locking

• Embedded: Ethernet, Modbus • Options: Ethernet IP, Modbus TCP, CANopen (RJ45 Daisy chain, Sub-D, screw terminals), PROFINET, Profibus DP V1, EtherCAT, DeviceNet, PowerLink

• Hoisting • Artificial lift • Extruders, crushers • Conveyors, mills • DC Bus sharing/ 4 Quadrant applications

Altivar Machine ATV900 success stories

Altivar Machine ATV900 success stories

Mataura Valley Milk - Seamlessly connecting farm to facility

Building the world's best nutritional plant to meet growing market demand requires connectivity and flexibility.

First Quantum Minerals Finland - 1400 metres below ground level

Altivar drive running a fan to exhaust the smoke of explosion in a mine 1400 metres below ground level.

Additional resources

Additional resources

Similar products you might be interested in

Similar products you might be interested in