Introducing TeSys Deca Advanced

Introducing TeSys Deca Advanced

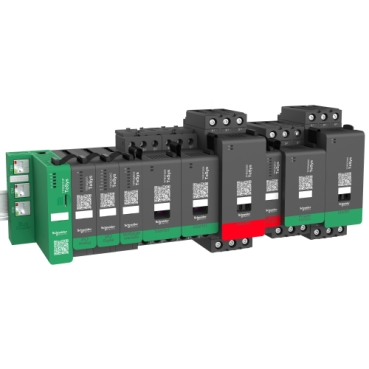

With power contactors, your systems perform reliably and efficiently, no matter the conditions. TeSys Deca Advanced electronic contactors support you in facing operational challenges such as hoisting equipment reliability and safety issues in harsh environments. The motor control helps overcome HVAC system struggles with energy efficiency, preventing up to 15% higher operational costs.

How can TeSys Deca Advanced assist me?

How can TeSys Deca Advanced assist me?

Enhancing Sustainability and Efficiency in HVAC Systems

TeSys Deca Advanced achieves up to 69% carbon savings per unit, reducing approximately 136.54 kg of CO2. Its compact design cuts panel size by up to 20%, optimizing space and simplifying integration. Engineered for harsh conditions, it performs reliably with up to 98% humidity and temperatures as high as 70°C, while mitigating fire risks, ensuring high levels of fire safety.

Ensuring Reliability and Durability in Steel Plant Hoisting

TeSys Deca Advanced doubles coil operating frequency to 2400 cycles per hour, reducing coil burning and enabling precise inching. It withstands temperatures up to 70°C and metal dust, ensuring continuous operation. EverLink™ terminals minimize maintenance needs under high shock and vibration. Its streamlined design simplifies installation and operation in crane-mounted control panels.

Benefits of TeSys Deca Advanced contactors

Sustainable and reliable TeSys Deca Advanced solutions help cut energy costs and ensure maintenance-free performance.Reduce 25% less wiring time

The ergonomic design with front-placed control circuits allows engineers to wire power lines before control lines, enhancing accessibility in the compact panel with better visibility in each connector, and significantly reducing the chance of miswiring.

Simplify your system with PLC direct control

The electronic coils' low power consumption results in substantial automation cost savings and streamlines wiring by enabling direct connection to PLCs' 24V 500mA output cards, simplifying circuit diagrams.

Ensure reliable connection with Everlink

The connection technology uses a unique creep-compensating design to maintain consistent pressure on the wiring over time, mitigating the loosening effects of shock or vibration.

Improve energy efficiency by electronic coil

The upgrade to electronic coils for IE4 motors results in 12% energy savings. This enhancement slashes coil energy usage by 80%, equating to a 480,000 KWH reduction throughout the HVAC application lifecycle.

Power Management features

TeSys Deca Advanced vs Deca (115~150 as an example)

Find the contactor that’s right for youContactor Dimension and Installation | 09A to 115A within compact size Hang on feature |

| |

Contactor Environment | Allow 360° mounting and floor mountingStrong shock and vibration withstandAnti-rust magnet and PCBA dust-protection cover |

| |

Contactor Main Pole Characteristics | EverLink main power connectionLess power dissipation |

| |

Contactor Control Circuit Characteristics | Wide band coilsLess coil consumption by electronic coilsReduce the contactor reference |

| |

Accessory and Spare Parts | New busbar design for front IP20 solutionNew control module and switching module as spare partRetrofit accessories including base and terminal adaptation |

|