Discover EcoStruxure Control Engineering

Discover EcoStruxure Control Engineering

EcoStruxure Control Engineering - Verification

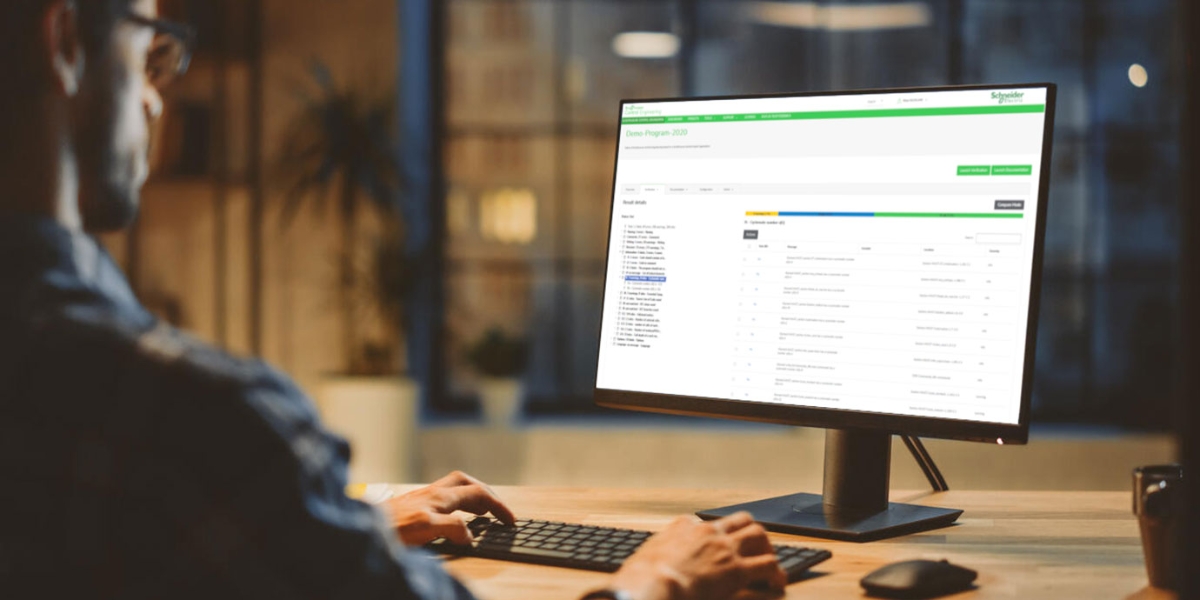

Improve your PLC code quality and conformity management with EcoStruxure Control Engineering – Verification, our static analysis tool that automates your code reviews.It analyses your PLC application with a chosen set of programming rules, whether the default set of good practice rules for improved code quality and simplified maintenance or a customized rules set for verifying conformity and facilitating compliance processes.

EcoStruxure Control Engineering - Converter

Easily modernize or migrate your PLC applications with EcoStruxure Control Engineering – Converter, our automatic code conversion tool.It converts a PLC application to another platform of the same or different vendor, while maintaining the same behaviour and semantics of the source application. It helps reduce migration time by up to 75% and migration costs by up to 40%.

EcoStruxure Control Engineering – Documentation and Monitoring

Improve understanding of PLC applications with EcoStruxure Control Engineering – Documentation, a reverse-engineering tool that generates an abstract representation of control applications to support testing, debugging, and change management.Facilitate troubleshooting of PLC systems with EcoStruxure Control Engineering – Monitoring, a real-time diagnostics solution based on EcoStruxure Control Engineering – Documentation that displays the live variable values from production to give a better understanding of the current state of your system.

What EcoStruxure Control Engineering can do for you

What EcoStruxure Control Engineering can do for you

About EcoStruxure Control Engineering

EcoStruxure Control Engineering is a set of four software engineering tools to support the management of your PLC applications by: • Automating tedious tasks, such as code review and code conversion, for increased productivity. • Ensuring quality and consistency of your installed base, for optimised maintenance. • Enabling you to retrieve information from your PLC applications, especially your legacy systems, for improved understanding.The tools are based on a unique technology that enables them to support the different PLC platforms in your installed base, including EcoStruxure Control Expert and EcoStruxure Machine Expert, as well as platforms from other vendors.

General information on EcoStruxure Control Engineering

Benefits of EcoStruxure Control Engineering

Engineering productivity

Increase engineering productivity by automating tedious but necessary tasks to support your work.

Code quality

Improve PLC code quality for greater consistency of your installed bases and optimised maintenance efforts.

Manage obsolescence

Minimize risk related to obsolescence with built-in knowledge of legacy systems.

Flexibility

One set of software tools to manage your mixed installed bases.

Features

Features

EcoStruxure Control Engineering - Verification

Manage the quality and conformity of a control program with a set of programming rules. • Dashboard view to give an overview of the evolution of application development and quality. • Result detail view to see all generated non-conformity messages to support the code review and improvement process. • Configurable rules set to enable verification based on a company or industry standard, or a default rules set is available made up of good practice programming rules. • Collaborative tool enabling project teams to work together and easily share results.EcoStruxure Control Engineering – ConverterAutomatically convert control applications for modernization and migration projects. • Reduce migration time by up to 75% by automatically converting the application logic, including memory organisation, data types, structure, and languages.• Information provided about what needs to be reviewed manually post-conversion with a supporting knowledge base.• Free conversion estimate phase to provide information on the convertibility of an application for a chosen conversion path.

EcoStruxure Control Engineering – DocumentationRetrieve information from an existing source code with reverse engineering. • Control Flow view for understanding application structure and Data Flow view for understanding relationships between variables. • Find all information in one place to understand the code contents, with cross-references available in Literal or Ladder for more details on the dependencies. • Built-in knowledge of legacy systems enabling support when original documentation is outdated or lost.

EcoStruxure Control Engineering – MonitoringFacilitate troubleshooting of control systems with a real-time diagnostics solution• Automatically generated Data Flow view providing a simple representation of the variables and their influences and dependencies.• See the live variable values displayed on the simplified data flow view to help understand the current state of the system.• Possible to integrate with existing production tools such as SCADA, version management systems and communication servers for greater efficiency.

Video presentation

Video presentation

EcoStruxure Control Engineering – Introduction

EcoStruxure Control Engineering is a set of software engineering tools to help you better manage your control programs and their quality throughout the application lifecycle.

Get a quick overview of the four software tools in our short introductory video.

Improving Control Code Quality with EcoStruxure Control Engineering

With the support of EcoStruxure Control Engineering, improve your PLC code quality and conformity for greater efficiency and easier maintenance.

Additional resources

Additional resources

Related products

Related products

CEGVAD4MPT | Verification | Subscription | Per program | 4 months |

| Documentation | Subscription | Per program | 4 months |

CEGVADY01P | Verification | Subscription | Per program | 12 months |

| Documentation | Subscription | Per program | 12 months |

CEGVADY10P | Verification | Subscription | Per program | 12 months |

| Documentation | Subscription | Per program | 12 months |

CEGVADY50P | Verification | Subscription | Per program | 12 months |

| Documentation | Subscription | Per program | 12 months |

CEGVADP01P | Verification | Perpetual | Per program | Perpetual |

| Documentation | Perpetual | Per program | Perpetual |

CEGVADP10P | Verification | Perpetual | Per program | Perpetual |

| Documentation | Perpetual | Per program | Perpetual |

CEGVADP50P | Verification | Perpetual | Per program | Perpetual |

| Documentation | Perpetual | Per program | Perpetual |

CEGVADP1UM | Verification | Perpetual | Per program | Perpetual |

| Documentation | Perpetual | Per program | |

CEGSERV12D | Service | Service | Service per half day | 12 months |

CEGSYSB1YT | Verification | Subscription | Per program | 12 months |

| Documentation | Subscription | Per program | 12 months |

| Converter | Subscription | Per program | 12 months |

CEGUNIB1YT | Verification | Subscription | Per program | 12 months |

| Documentation | Subscription | Per program | 12 months |