Whether you are the CEO, CTO, or a project owner, a lot is at stake when selecting software partners. Implementing the wrong software, or even deploying good software the wrong way, can set your business up for failure before you even get started.

Choose your digital partners carefully.

“In the industrial sector, where software frequently requires deep domain expertise, the quality of the support users get when acquiring subscription software can dramatically impact the outcomes they get from the software.” ARC

Not all software is created equal and not all software providers have deep domain expertise in industrial operations. When selecting a software partner, ask about:

Shaping your future

“Future factories will be high-tech, software-driven engines of customized mass production. They will be more automated, more connected, and integrated, and more information-intensive than ever before. They will be organized for greater speed, flexibility, productivity, and efficiency. The people who work in them will have advanced skills and technical competency with the ability to work cross-functionally across the connected enterprise.” Manufacturing Leadership Council

Choose your digital partners carefully.

“In the industrial sector, where software frequently requires deep domain expertise, the quality of the support users get when acquiring subscription software can dramatically impact the outcomes they get from the software.” ARC

Not all software is created equal and not all software providers have deep domain expertise in industrial operations. When selecting a software partner, ask about:

- Trusted and proven domain knowledge in your specific industry

- Flexible and scalable software-as-a-service (SaaS) solutions

- Seamless dataflow across the entire lifecycle—from design and build to operate and maintain

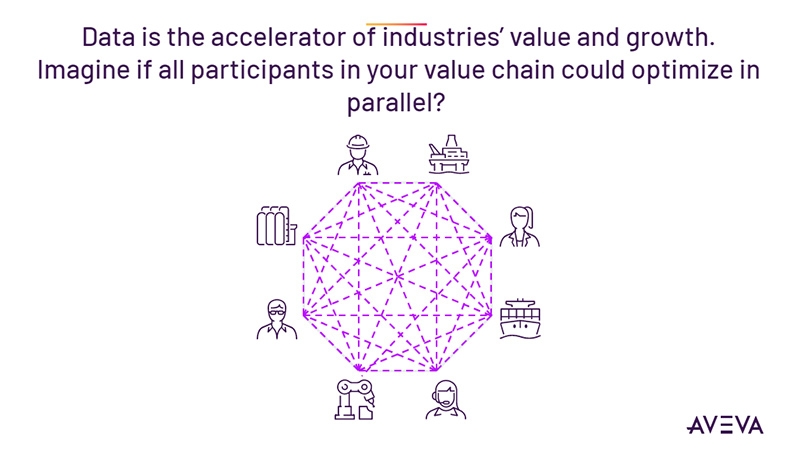

- Federated data that enables you to unlock the power of the connected industrial economy

- Integrated and intuitive user experience across systems

- Fully combined artificial intelligence and digital twin capabilities

- Extended reality (virtual, augmented, and mixed reality) and data visualization

- Smart analytics onsite, in the cloud, and remote

- Ecosystem of collaboration partners

- World-class industrial services

Shaping your future

“Future factories will be high-tech, software-driven engines of customized mass production. They will be more automated, more connected, and integrated, and more information-intensive than ever before. They will be organized for greater speed, flexibility, productivity, and efficiency. The people who work in them will have advanced skills and technical competency with the ability to work cross-functionally across the connected enterprise.” Manufacturing Leadership Council