Discover Modicon M580

Discover Modicon M580

General information about Modicon M580

The Modicon M580 ePAC is the first high-end integrated controller built for EcoStruxure™ Plant in an open, flexible, reliable, sustainable, safe and secure architecture. It features redundant controllers and safety controllers (safety PLC SIL3) with native Ethernet and cybersecurity embedded in its core.

Process or safety processors both use the same Modicon X80 I/O modules platform and EcoStruxure Control Expert (formerly known as Unity Pro) software for programming and configuration.Benefits of Modicon M580

Reduced time to profit

Save up to 3 weeks on a 3-month project, resulting in $2 million of extra production at launch

Cybersecurity

Manage operating risks and save an average of >$1.25 million per year in related costs with certified inherent cybersecurity built into the controller.

Process efficiency

Improve process efficiency through 5x faster scan time and save up to $2 million per year for a typical high-volume manufacturing plant thanks to the latest processing technologies.

Process safety

The Modicon M580 safety controller is the only PAC in the marketplace that offers 100% ROI within three months of implementation.

Video presentations

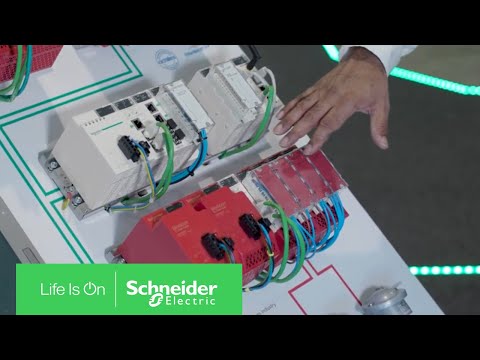

Modicon M580 — the world's first ePAC

Kevin Gag, Senior Solutions Consultant at the Coventry Innovation Hub, showcases Modicon M580 ePAC (Ethernet programmable automation controller) which offers openness, flexibility, robustness and sustainability.

Modicon M580 safety controller

Dave Sutton, Marketing Manager of Automation Products in the UK, discusses the new Modicon M580 safety controller which is suitable for more critical applications.

Modicon M580 features

Openness and transparency: Native Ethernet capabilities (EtherNet/IP and Modbus TCP), large scope of protocols and fieldbus supported: OPC UA, IEC 61850, RTU (DNP3 and IEC 60870), PROFIBUS DP, Serial, AS-I, CANopen

Connectivity: easy integration of field devices and third-party products through standard FDT technology

Smart Engineering: EcoStruxure Control Expert Software platform saves engineering and commissioning time through simulation tools, predefined libraries and code checking

Greater application code quality: through EcoStruxure Control Engineering software tools including verification, converter (easy migration from non-Schneider Electric PLC/PAC), documentation and monitoring

Easy evolution during operations without stopping your process via Change Configuration on the Fly functions (CCOTF)

Scalable high-availability fault-tolerant architecture: redundant (hot-standby) processors, power supplies, communication networks and switches

Reliability and robustness based on the proven X80 I/O platform and compliance with a large number of international environmental standards

Optimised maintenance with native module diagnostics (DDT), faulty-device replacement (FDR) and preventive maintenance features for power supplies

- Modicon M580 Safety is certified for machine and process safety applications

- SIL3 rating certified by TÜV Rheinland: dual execution code in safety processor and coprocessor, X80 Safety I/O and power supplies

- Common safety: combined safety and standard non-interfering modules in the same PAC configuration to reduce spare parts, training costs and eliminate the need for complex communications between safety and process PLC

- Openness to smart Ethernet safety devices integration with CIP Safety

Easy configuration and compliance with regulations

Firmware and software encrypted and digitally signed

Firewall features — access control list and data flow control

Traceability of security events (Syslog)

Secured communications to engineering station and PLC-to-PLC communications with IPSEC

Native cybersecurity to SCADA and IIoT applications with OPC UA (in-rack or PC-based software) and secure RTU (in-rack) protocols

• Capitalise on your code through software converter tools from legacy software (PL7/Concept) embedded into EcoStruxure Control Expert or additional tools (UMAC, EcoStruxure Control Engineering).• Capitalise on your cabling through hardware kits and connect your existing I/O to M580 or Quantum S908 RIO, bus managed by M580.• Capitalise on your legacy protocols: Modicon M580 supports protocols used in legacy Modicon and Télémécanique platforms such as Modicon S908 coaxial bus, Modbus Plus, Ethway, Global Data or Interbus-S.• Dedicated service teams to support modernisation

Modicon M580 success stories

Simplify operation with Modicon M580

With a focus on innovation and cybersecurity, Suez Environment, a global leader in water and wastewater treatment, was able to simplify operation and maintenance with a Modicon M580.

From sugar to energy, safely

Wilmar has been working with Schneider Electric for more than a decade and chose Modicon M580 safety PLCs to replace multiple controllers which were previously monitored individually.

Efficient innovation

Saint-Gobain, one of the largest construction material manufacturers in the world, improves its energy usage and cuts costs with Modicon M580 and EcoStruxure solutions.

Smart manufacturing for the steel industry

Chinese steel giant, Baosteel, transforms its steel manufacturing with EcoStruxure Plant, increasing production by up to 30%, improving worker safety and reducing labour costs.