Warehouse management and material handling

Improve steel operations with autonomous yards, crane upgrades, and warehouse management solutions.

With the Integrated Autonomous Crane System (IACS), steel manufacturers can use the continuously updated Warehouse Management System (WMS). Here are the key benefits of our solutions:

- Improved personnel safety

- Increased material movements efficiency

- Real-time strategic decision making

Improve inventory tracking, crane movement, and yard safety with warehouse management solutions designed to boost productivity and reduce manual tasks. They adapt to your workflow for smarter decisions.

Crane automation helps steel manufacturers integrate cranes into their operational processes, reduce manual tasks, and improve safety and efficiency through intelligent scheduling and advanced algorithms.

The warehouse management system is a logistics optimisation software for steel, enabling real-time tracking, crane coordination, and smart storage across all transport types. It is designed to optimise every crane movement.

Key values

Safety functions

Streamline machine safety with detailed risk analysis and support for required safety functions.

Anti-sway system

Advanced anti-sway system reduces load movement and improves crane positioning.

Real-time scanning

Live 3D scanning detects forms and measures in motion during crane operations.

Real-time CCTV

Remote CCTV technology enables live control of crane and warehouse activity.

3D dynamic trajectories

The real-time detection adjusts crane paths for safety zones and obstacle avoidance.

Grab control

Optimised four-rope grab regulation enhances movement, digging, and crane performance.

Three-axis movements

Crane travel uses three-axis coordination to boost speed and logistics efficiency.

Smart anti-collision

The system detects sensor mismatches and adjusts the crane speed to ensure continuous operation.

Key values

Safety functions

Streamline machine safety with detailed risk analysis and support for required safety functions.

Anti-sway system

Advanced anti-sway system reduces load movement and improves crane positioning.

Real-time scanning

Live 3D scanning detects forms and measures in motion during crane operations.

Real-time CCTV

Remote CCTV technology enables live control of crane and warehouse activity.

3D dynamic trajectories

The real-time detection adjusts crane paths for safety zones and obstacle avoidance.

Grab control

Optimised four-rope grab regulation enhances movement, digging, and crane performance.

Three-axis movements

Crane travel uses three-axis coordination to boost speed and logistics efficiency.

Smart anti-collision

The system detects sensor mismatches and adjusts the crane speed to ensure continuous operation.

Turnkey projects

One expert team for your hoisting project: design, install, test, and commission

Consulting services

Boost crane operations and warehouse management efficiency with our surveys, safety, and specification support.

Operational excellence

Our experts assess your operations and deliver scalable solutions for warehouse digitisation.

After-sales support

We support your hoisting needs with expert help and great service – anytime, anywhere.

Safety

Meet local and global safety standards, protect employees, and prioritise zero-accident performance.

Efficiency

Reduce or eliminate repetitive work, extend equipment life, and enhance material tracking and inventory control.

Availability

Modernise ageing infrastructures to minimise downtime, operational failures and reduce major breakdowns.

Quality

Reduce handling errors, eliminate scrap of finished products, and improve tracking and customer satisfaction.

The hoisting business centre is ready to support your next project and assist with any hoisting application in the metals industry. Get in touch with us today – we're here to help.

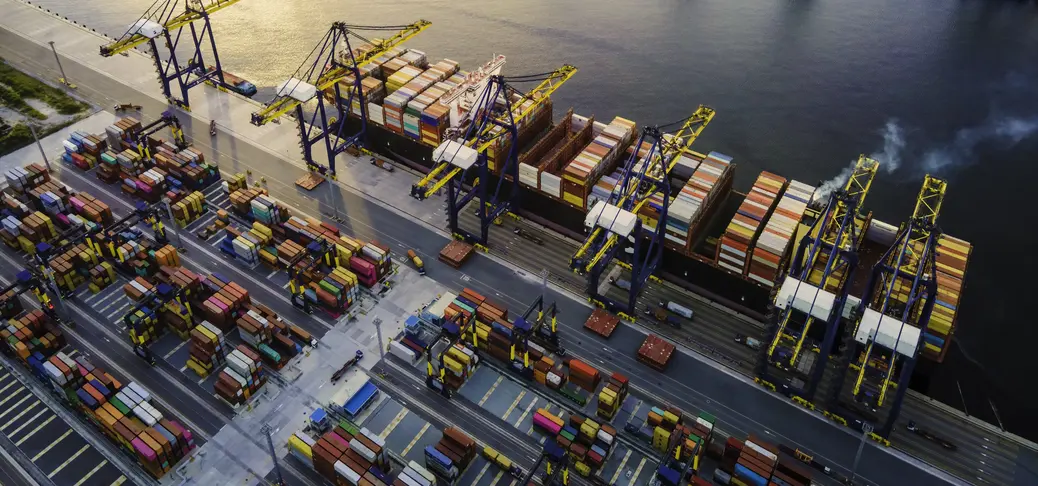

How digital transformation and automation of cranes and yard in metals manufacturing can transform inventory and warehouse management?

Schneider Electric helps metal industries digitise manufacturing operations and warehouse management through software-centric crane modernisation and autonomous yard solutions to make them efficient, sustainable, and resilient.

As an industrial technology leader with extensive IoT and data analytics expertise, we can help bring unprecedented flexibility and automation to your material handling operations through connected products and digital solutions to improve energy efficiency and lower carbon footprint.

Discover EcoStruxure for Metals, our IoT-enabled system, to help bring innovation and establish an automation standard to be replicated in the yard and warehouse management in steel manufacturing industries to improve performance and reduce cost.

Our operational and scalable solutions enable seamless integration of semi and fully automated cranes into steel manufacturing processes and improve personnel safety, decision making, inventory, and warehouse management.

Explore our Integrated Autonomous Crane System (IACS) that digitises and fully automates crane operations in your facility.

Steel manufacturers can continuously update the Warehouse Management System (WMS) by modifying it according to specific demands, new activities, or production arrangements and gain from predictive maintenance and remote monitoring solutions.

Metal industries rely on Schneider Electric for unlocking smart functions that combine machine safety, smart sensors, load anti-sway, real-time scanning, and dynamic trajectories to drive operational profitability safely.

Our Hoisting Business Centre experts enable you to deliver your projects successfully whilst consulting experts provide customisable and scalable support on crane and warehouse management besides providing first-rate after-sales support.

Schneider Electric helps metal industries develop a collaborative digital environment for logistics and warehouse management to ensure compliance with local and global safety standards, material tracking and inventory control, modernisation of infrastructure to minimise downtime and breakdowns, and increased customer satisfaction.