End-to-End Motor Management Solutions from the Motor Expert

Watch how our holistic motor management solutions can optimise motor availability and increase savings.

Motor management

We help you to optimise and simplify your motor management solution while maintaining the performance of your operations and processes.

Discover five motor management areas every motor expert focuses on

Motor experts concentrate on five essential areas to keep motors running at their best: performance monitoring, energy efficiency, maintenance planning, safety compliance, and lifecycle management. By focusing on these, they ensure motors operate smoothly, avoid unexpected downtime, lower operating costs, and achieve a longer service life.

How do you approach motor management?

Our motor management approach delivers products and solutions for machine, process, and building applications. It enables you to design and select the best fit of the offer portfolio to achieve sustainable optimisation in CapEx and OpEx.

Web app

EcoStruxure™ Motor Management Design web app

Make insightful design choices with a unique application dedicated to conceptual design and offer selection. It performs multiple calculations for motor starting, power quality, and energy saving, to help you make an informed decision for motor management.

Online tool

EcoStruxure Motor Control Configurator

Configure your electrical motor starter with a step-by-step online solution. This guidance helps to build a complete setup, with four technologies available: speed drive, soft starter, direct starter, and TeSys Island.

Get to know motor management applications

Each application segment contains various offers in motor direct starters, protection, soft starters, and variable speed drives based on key priorities.

Explore our offer for machine applications

Discover our motor management solution architectures for machines to lower cost optimisation and boost machine’s performance.

Explore our offer for process applications

Increase safety and energy efficiency and decrease downtime with our targeted processes and infrastructure installations.

Check our resources

Explore our offer for building applications

Utilise our solutions dedicated to buildings and ensure improved safety of people and assets.

Check our resources

Sustainable motor management

Motor management optimisation is a sustainable way to improve application performance while reducing energy usage and overall costs. Get to know our e-guide to better understand the impact of holistic motor management solutions.

Check our digital tools for seamless interactions

What is motor management?

Electrical motor management is usually associated with the overall maintenance of the motor; however, it is not limited to that. Our motor management holistic approach helps end users, equipment manufacturers, and designers coping with mechanical, electrical, and maintenance challenges for motors, controls, equipment selection and sizing, power factor, harmonic mitigation, and service continuity.

Our offer supports sustainable motor integration in electrical systems for industrial, machine and building applications. Made up of 5 pillars, it involves expert services and software for motor applications, advanced motor control, power quality, motor protection and control systems and asset management. An efficient motor management can help with reducing impact of motors during start-up and operation, increase power quality and production efficiency, reduce costs of unscheduled downtime or upkeeping, eliminate unnecessary inventory build-up, and more.

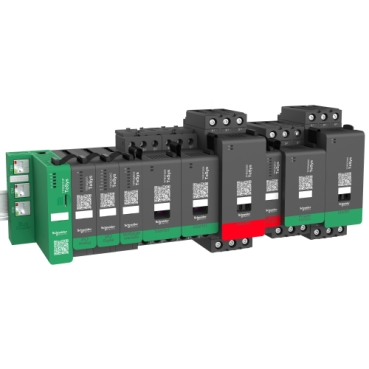

Motor management solutions by Schneider Electric

Our motor management solutions are based on properly designed and selected advanced technologies, robust power system architectures, motor control configurators, and motor management design tools for machines, processes, and buildings.

Our architectures can be divided into two broad categories:

Digitised architecture, performance-driven and fully connected with transparent data reporting. It is instrumental in efficient energy management and power quality management.

Core architecture, offering balanced performance, contactor, soft starter, and variable speed drive solutions.

Why a motor management programme?

Our motor management programme enables installation maintenance and management by supporting cost-effective decisions whenever a motor fails. It will help you reducing downtime and energy costs, ensuring that replacement motors are readily available.

Who is a motor expert and why should I consult one?

A motor expert is a professional who specializes in the performance and reliability of motors. From identifying issues to boosting efficiency, a motor expert helps keep operations smooth, cuts costly downtime, and extends motor life. Consulting a motor expert ensures your systems stay dependable and cost-effective.

How can a motor expert help optimize motor performance?

A motor expert improves performance by conducting regular monitoring, efficiency assessments, and preventive maintenance. They detect early signs of wear, correct alignment issues, and recommend energy-saving upgrades to optimise motor use. With their expertise, motors face fewer breakdowns, operate more reliably, and deliver consistent output. By keeping motors at peak efficiency, a motor expert extends equipment life and also helps lower operating costs.

What are Schneider Electric’s motor management solutions?

Schneider Electric’s motor management solutions provide intelligent protection, control, and monitoring for motors across industries. They improve efficiency, extend motor life, and help reduce downtime by combining advanced diagnostics, automation, and energy optimization in one integrated system.

What are the five key focus areas of motor management?

The five key focus areas of motor management are protection, control, monitoring, diagnostics, and energy efficiency. Together, they ensure motors run safely, perform reliably, reduce downtime, optimize energy use, and extend equipment life for better overall productivity.

What applications are covered by motor management?

Motor management covers applications in pumping, HVAC, material handling, conveyors, compressors, and industrial process control. It ensures reliable motor performance, reduces downtime, and improves energy efficiency across diverse sectors like manufacturing, water, oil and gas, and infrastructure.

What solutions are available for machine applications?

For machine applications, motor management solutions include protection relays, soft starters, variable speed drives, and intelligent motor controllers. These ensure precise control, energy savings, safety, and reliability in packaging, material handling, textile, and processing machinery.

What offerings are provided for process applications?

For process applications, Schneider Electric provides motor protection relays, intelligent controllers, and drives that boost reliability, save energy, support predictive maintenance, and ensure continuous operation in industries like oil and gas, mining, and water treatment.

What types of products support building-focused motor management?

Building-focused motor management is supported by soft starters, variable speed drives, protection relays, and monitoring devices. These solutions improve HVAC, pumping, and ventilation performance, ensuring energy efficiency, safety, and reliable operation in commercial and residential buildings.