Discover PacDrive 3 LMC Eco and LMC Pro2

Discover PacDrive 3 LMC Eco and LMC Pro2

High performance motion controller

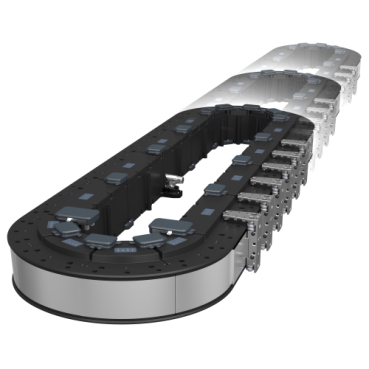

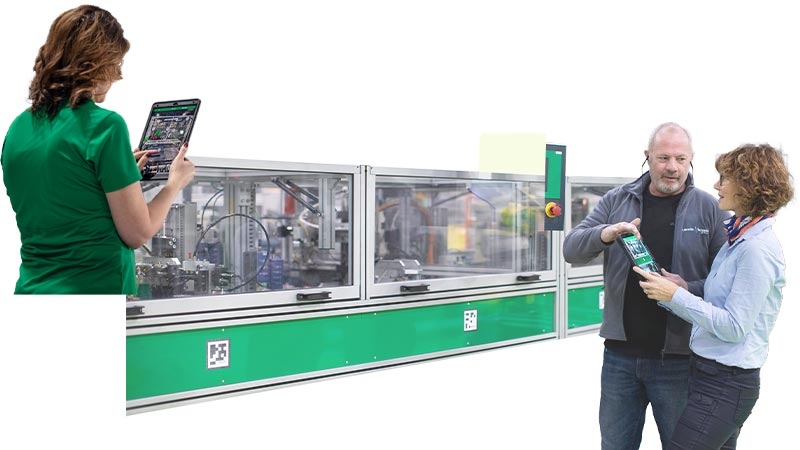

The PacDrive 3 LMC controllers, Eco and Pro2 series, provide a scalable hardware platform and scalable performance for synchronizing up to 130 servo axes with a 1 msec network update rate and support for up to 255 virtual axes. They integrate PLC, HMI interfaces, and IT functionalities into a single hardware platform, for complete automation solutions including robotics and multicarrier.

Benefits

Benefits

Scalable

One engineering software

Efficient

PacDrive 3 LMC Eco and LMC Pro2 features

PacDrive 3 LMC Eco and LMC Pro2 features

Facts about PacDrive 3 LMC Eco and LMC Pro2

EcoStruxure Machine Expert

- CoDeSys based, compliant to IEC 61131-3

- Application libraries and open-source software are available

- Libraries for implementing PackML guidelines and Weihenstephan standard

- FDA and PLCopen compliant library functions

- Program up to 4,096 dynamic electronic cam disks

- From 0 to 130 servo drives/robot axes, in parallel up to 250 virtual axes

- 1 msec network update rate for 130 servo axes

- All controllers have an integrated PLC (5 μsec for 1000-bit instructions)

- Network with up to 20 controllers/machines possible

- Real-time controller-to-controller communication via Sercos

- Integrated high-speed I/O, externally expandable

- Full Ethernet-based communication with Sercos for I/O, motion (robotics), and safe communication

- Realtime controller-to-controller communication online level via Sercos, in parallel to Sercos communication on the field level

- Option modules for additional protocols

- Supporting other RT Ethernet solutions, standard IEC field busses, and as well TCP/IP communication

Applications

Machine control

Explore morePackaging machine automation

Explore more

Additional Links

Additional Links