1. How can Energies and Chemicals thrive in the age of energy transition?

Energies and Chemicals represent one of the largest industries globally which is facing a major evolution. It will take a partner with knowledge and credibility coupled with world-class process and energy technologies, endpoint-to-cloud connected products, controls, software, and services across the entire lifecycle, to create sustainable profitability for the future. Schneider Electric is well-equipped with appropriate oil field solutions as well as oil and gas services that enhance the reliability and safety of oil, gas, and petrochemical industry plants, accelerate IoT connectivity and optimise operations by monitoring performance. Our oil field solutions are based on EcoStruxure, an exclusive IoT-based architecture inclusive of connected products, edge control, apps, analytics and services. It carries the potential to offer robust solutions to multiple industries and help stimulate the growth of the industry with digitisation.

2. How is IoT impacting the energy and chemical industry?

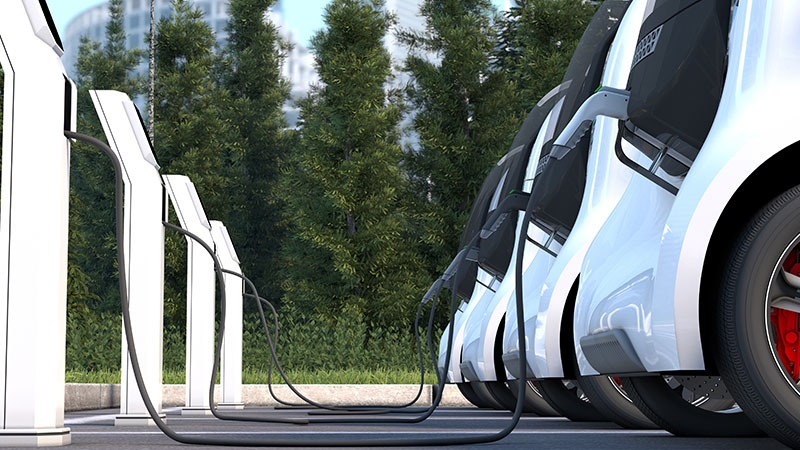

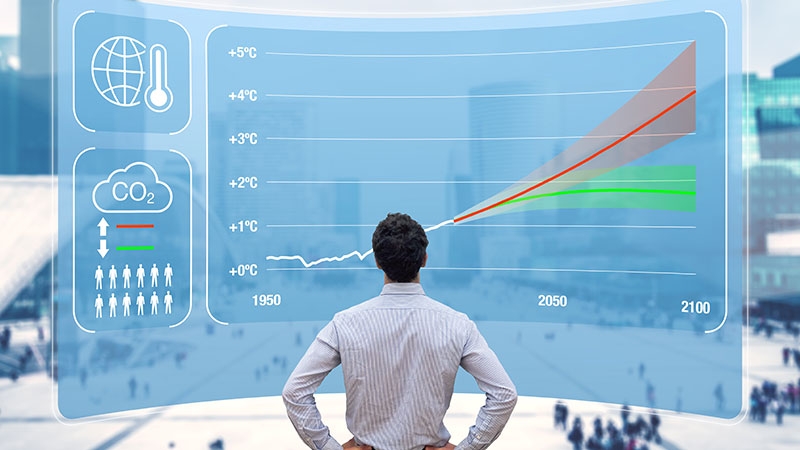

IoT is an acronym that stands for the term Internet of Things. It connects tools, machines, and sensors on the shop floor to give managers and engineers direct visibility into the production process. IoT has proven extremely beneficial in the energy and chemical industry for carrying out complex tasks like onshore and offshore monitoring, drilling management, transport shipping, efficient operations in downstream, improved security, and carbon footprint reduction. Our digital energy solutions provide our customers with operational resilience delivered by design optimisation, unified process simulation, and asset performance management to empower engineering and operations with precise and timely data.

3. Importance of software solutions for the energy and chemical industry

At Schneider Electric, our competent team of experts is constantly looking to configure new solutions that can streamline operations and cut costs. One of the best ways to accelerate innovation and sustainability in the energy and chemicals industry is incorporating software solutions for the acceleration of digital transformation. Leveraging the best of power, process, and digital Schneider Electric’s sustainable energy management and automation solutions, combined with AVEVA’s integrated data platform and leading-edge industrial software, we are enabling energy companies to harness the power of information, AI, and human insight to drive efficient, sustainable performance. Realise your vision to increase profitability and minimise risk, while empowering your people through connected capabilities and technologies.