ATV340U30N4E

SRVEW1YDRV05

SRVEW3YDRV05

| Range of product | Altivar Machine ATV340 |

|---|---|

| Product or component type | Variable speed drive |

| Product specific application | Machine |

| Mounting mode | Cabinet mount |

| Variant | Standard version |

| Communication port protocol | Modbus serial Modbus TCP EtherNet/IP |

| Network number of phases | 3 phases |

| Supply frequency | 50...60 Hz +/- 5 % |

| [Us] rated supply voltage | 380...480 V - 15...10 % |

| Nominal output current | 7.2 A |

| Motor power kW | 4 kW for normal duty 3 kW for heavy duty |

| Motor power hp | 3 hp for heavy duty 5 hp for normal duty |

| EMC filter | Class C3 EMC filter integrated |

| IP degree of protection | IP20 |

| Discrete input number | 5 |

|---|---|

| Discrete input type | PTI programmable as pulse input: 0…30 kHz, 24 V DC (30 V) DI1...DI5 safe torque off, 24 V DC (30 V), impedance: 3.5 kOhm programmable |

| number of preset speeds | 16 preset speeds |

| Discrete output number | 2.0 |

| Discrete output type | Programmable output DQ1, DQ2 30 V DC 100 mA |

| Analogue input number | 2 |

| Analogue input type | AI1 software-configurable current: 0...20 mA, impedance: 250 Ohm, resolution 12 bits AI1 software-configurable temperature probe or water level sensor AI1 software-configurable voltage: 0...10 V DC, impedance: 31.5 kOhm, resolution 12 bits AI2 software-configurable voltage: - 10...10 V DC, impedance: 31.5 kOhm, resolution 12 bits |

| Analogue output number | 1 |

| Analogue output type | Software-configurable voltage AQ1: 0...10 V DC impedance 470 Ohm, resolution 10 bits Software-configurable current AQ1: 0...20 mA impedance 500 Ohm, resolution 10 bits |

| Relay output number | 2 |

| Output voltage | <= power supply voltage |

| Relay output type | Relay outputs R1A Relay outputs R1C electrical durability 100000 cycles Relay outputs R2A Relay outputs R2C electrical durability 100000 cycles |

| Maximum switching current | Relay output R1C on resistive load, cos phi = 1: 3 A at 250 V AC Relay output R1C on resistive load, cos phi = 1: 3 A at 30 V DC Relay output R1C on inductive load, cos phi = 0.4 and L/R = 7 ms: 2 A at 250 V AC Relay output R1C on inductive load, cos phi = 0.4 and L/R = 7 ms: 2 A at 30 V DC Relay output R2C on resistive load, cos phi = 1: 5 A at 250 V AC Relay output R2C on resistive load, cos phi = 1: 5 A at 30 V DC Relay output R2C on inductive load, cos phi = 0.4 and L/R = 7 ms: 2 A at 250 V AC Relay output R2C on inductive load, cos phi = 0.4 and L/R = 7 ms: 2 A at 30 V DC |

| Minimum switching current | Relay output R1B: 5 mA at 24 V DC Relay output R2C: 5 mA at 24 V DC |

| Physical interface | 2-wire RS 485 |

| Connector type | 3 RJ45 |

| Method of access | Slave Modbus RTU Slave Modbus TCP |

| Transmission rate | 4.8 kbit/s 9.6 kbit/s 19.2 kbit/s 38.4 kbit/s |

| Transmission frame | RTU |

| Number of addresses | 1…247 |

| Data format | 8 bits, configurable odd, even or no parity |

| Type of polarization | No impedance |

| 4 quadrant operation possible | True |

| Asynchronous motor control profile | Optimized torque mode Variable torque standard Constant torque standard |

| Synchronous motor control profile | Reluctance motor Permanent magnet motor |

| Pollution degree | 2 conforming to IEC 61800-5-1 |

| Maximum output frequency | 0.599 kHz |

| Acceleration and deceleration ramps | S, U or customized Linear adjustable separately from 0.01...9999 s |

| Motor slip compensation | Adjustable Not available in permanent magnet motor law Can be suppressed Automatic whatever the load |

| Switching frequency | 2...16 kHz adjustable 7...16 kHz with derating factor |

| Nominal switching frequency | 4 kHz |

| Braking to standstill | By DC injection |

| Brake chopper integrated | True |

| Line current | 8.6 A at 380 V (normal duty) 6.8 A at 480 V (normal duty) 10.7 A at 380 V (heavy duty) 8.5 A at 480 V (heavy duty) |

| Line current | 10.7 A at 380 V without line choke (heavy duty) 8.5 A at 480 V without line choke (heavy duty) 8.6 A at 380 V with external line choke (normal duty) 6.8 A at 480 V with external line choke (normal duty) 6.6 A at 380 V with external line choke (heavy duty) 5.3 A at 480 V with external line choke (heavy duty) |

| Maximum input current | 10.7 A |

| Maximum output voltage | 480 V |

| Apparent power | 6.7 kVA at 480 V (normal duty) 7.1 kVA at 480 V (heavy duty) |

| Maximum transient current | 10.2 A during 60 s (normal duty) 12.6 A during 2 s (normal duty) 13 A during 2 s (heavy duty) 11 A during 60 s (heavy duty) |

| Electrical connection | Screw terminal, clamping capacity: 1.5...4 mm² for line side Screw terminal, clamping capacity: 4...6 mm² for DC bus Screw terminal, clamping capacity: 1.5...4 mm² for motor Screw terminal, clamping capacity: 0.2...2.5 mm² for control |

| Prospective line Isc | 5 kA |

| Base load current at high overload | 7.2 A |

| Base load current at low overload | 9.3 A |

| Power dissipation in W | Natural convection: 78 W at 380 V, switching frequency 4 kHz (heavy duty) Forced convection: 78 W at 380 V, switching frequency 4 kHz (heavy duty) Natural convection: 96 W at 380 V, switching frequency 4 kHz (normal duty) Forced convection: 96 W at 380 V, switching frequency 4 kHz (normal duty) |

| Electrical connection | Line side: screw terminal 1.5...4 mm²/AWG 14...AWG 12 DC bus: screw terminal 4...6 mm²/AWG 12...AWG 10 Motor: screw terminal 1.5...4 mm²/AWG 14...AWG 12 Control: screw terminal 0.2...2.5 mm²/AWG 24...AWG 12 |

| With safety function Safely Limited Speed (SLS) | True |

| With safety function Safe brake management (SBC/SBT) | True |

| With safety function Safe Operating Stop (SOS) | False |

| With safety function Safe Position (SP) | False |

| With safety function Safe programmable logic | False |

| With safety function Safe Speed Monitor (SSM) | False |

| With safety function Safe Stop 1 (SS1) | True |

| With sft fct Safe Stop 2 (SS2) | False |

| With safety function Safe torque off (STO) | True |

| With safety function Safely Limited Position (SLP) | False |

| With safety function Safe Direction (SDI) | False |

| Protection type | Thermal protection: motor Safe torque off: motor Motor phase loss: motor Thermal protection: drive Safe torque off: drive Overheating: drive Overcurrent: drive Output overcurrent between motor phase and earth: drive Output overcurrent between motor phases: drive Short-circuit between motor phase and earth: drive Short-circuit between motor phases: drive Motor phase loss: drive DC Bus overvoltage: drive Line supply overvoltage: drive Line supply undervoltage: drive Input supply loss: drive Exceeding limit speed: drive Break on the control circuit: drive |

| Width | 85.0 mm |

| Height | 270.0 mm |

| Depth | 232.5 mm |

| Net weight | 2.2 kg |

| Continuous output current | 9.3 A at 4 kHz for normal duty 7.2 A at 4 kHz for heavy duty |

| Operating altitude | <= 3000 m with current derating above 1000m |

|---|---|

| Operating position | Vertical +/- 10 degree |

| Product certifications | UL CSA TÜV EAC CTick |

| Marking | CE |

| Standards | IEC 61800-3 IEC 61800-5-1 IEC 60721-3 IEC 61508 IEC 13849-1 UL 618000-5-1 UL 508C |

| Assembly style | With heat sink |

| Electromagnetic compatibility | Electrostatic discharge immunity test level 3 conforming to IEC 61000-4-2 Radiated radio-frequency electromagnetic field immunity test level 3 conforming to IEC 61000-4-3 Electrical fast transient/burst immunity test level 4 conforming to IEC 61000-4-4 1.2/50 µs - 8/20 µs surge immunity test level 3 conforming to IEC 61000-4-5 Conducted radio-frequency immunity test level 3 conforming to IEC 61000-4-6 |

| Environmental class (during operation) | Class 3C3 according to IEC 60721-3-3 Class 3S3 according to IEC 60721-3-3 |

| Maximum acceleration under shock impact (during operation) | 70 m/s² at 22 ms |

| Maximum acceleration under vibrational stress (during operation) | 5 m/s² at 9...200 Hz |

| Maximum deflection under vibratory load (during operation) | 1.5 mm at 2...9 Hz |

| Permitted relative humidity (during operation) | Class 3K5 according to EN 60721-3 |

| Volume of cooling air | 19.0 m3/h |

| Type of cooling | Forced convection |

| Overvoltage category | Class III |

| Regulation loop | Adjustable PID regulator |

| Noise level | 51.2 dB |

| Pollution degree | 2 |

| Ambient air transport temperature | -40…70 °C |

| Ambient air temperature for operation | -15…50 °C without derating (vertical position) 50…60 °C with derating factor (vertical position) |

| Ambient air temperature for storage | -40…70 °C |

| Isolation | Between power and control terminals |

| Unit Type of Package 1 | PCE |

|---|---|

| Number of Units in Package 1 | 1 |

| Package 1 Height | 11.000 cm |

| Package 1 Width | 37.000 cm |

| Package 1 Length | 32.000 cm |

| Package 1 Weight | 2.910 kg |

| Unit Type of Package 2 | P06 |

| Number of Units in Package 2 | 12 |

| Package 2 Height | 75.000 cm |

| Package 2 Width | 60.000 cm |

| Package 2 Length | 80.000 cm |

| Package 2 Weight | 47.920 kg |

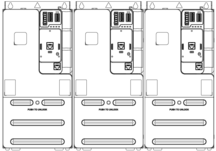

X1 | X2 | X3 | |||

mm | in. | mm | in. | mm | in. |

≥ 100 | ≥ 3.94 | ≥ 100 | ≥ 3.94 | ≥ 60 | ≥ 2.36 |

Possible, at ambient temperature ≤ 50 °C (122 °F)

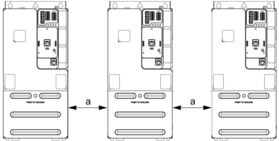

a ≥ 50 mm (1.97 in.) from 50...60°C, no restriction below 50°C

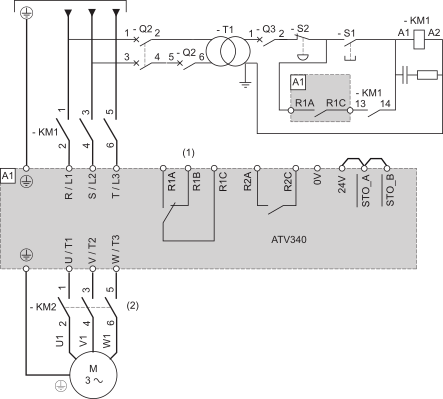

(1) : Use relay output R1 set to operating state Fault to switch Off the product once an error is detected.

NOTE :

• Press S1 until the initialization of the drive is finished.

• An external 24V power supply can be connected so that the control part of the drive is always power supplied.

(1) : Use relay output R1 set to operating state Fault to switch Off the product once an error is detected.

(2) : Command of KM2 can be done by using the [Output contactor cmd] OCC function. For more information, refer to the programming manual.

NOTE :

• Close upstream contactor, then press S1 after the initialization of the drive is finished.

• An external 24V power supply can be connected so that the control part of the drive is always power supplied.

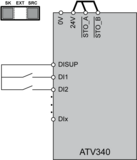

(1) : 24V In, Out, maximum supply current 200 mA is provided,

(2) : STO - Safe Torque Off, see ATV340 Embedded safety function manual NVE64143

(3) : PTI - Pulse Train In, from external source (eg.PLC) Pulse - Direction or A-B signals can be connected

(4) : PTO - Pulse Train Out, can be used to connect to a 2nd ATV340 PTI

(5) : To connect a motor position feedback encoder

(6) : Digital output, e.g. to connect a contactor, also usable as DI

(7) : Digital inputs

(8) : Analog output, e.g. to connect a meter

(9) : Analog input, e.g. from potentiometer

(10) : Differential analog input, e.g. as speed reference from external PLC differential, +/– 10 V

(11) : 2 advanced Ethernet ports ETH1, ETH2 (ATV340•••••E) or 2 Sercos III ports S3P1, S3P2 (ATV340•••••S)

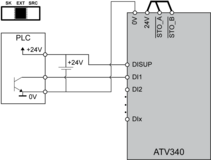

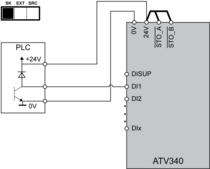

Using DISUP Signal

In SRC position DISUP outputs 24 V. In SK position DISUP is connected to 0 V.

Positive Logic, Source, European Style

Negative Logic, Sink, Asian Style

Negative Logic, Sink, Asian Style

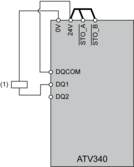

Positive Logic, Source, European Style, DQCOM to +24V

(1) Relay or valve

Negative Logic, Sink, Asian Style, DQCOM to 0V

(1) Relay or valve

Positive Logic, Source, European Style, DQCOM to +24V

(1) Relay or valve

Negative Logic, Sink, Asian Style, DQCOM to 0V

(1) Relay or valve

40 °C (104 °F) - Mounting type A and B

40 °C (104 °F) - Mounting type A and B

50 °C (122 °F) - Mounting type A and B

50 °C (122 °F) - Mounting type A and B

In : Nominal Drive Current

SF : Switching Frequency

Items usually bought together

Need more information? Check our technical FAQs!

Easily find answers to the most frequently asked questions.