Discover EcoStruxure Process Expert for AVEVA System Platform

Discover EcoStruxure Process Expert for AVEVA System Platform

About EcoStruxure Process Expert for AVEVA System Platform

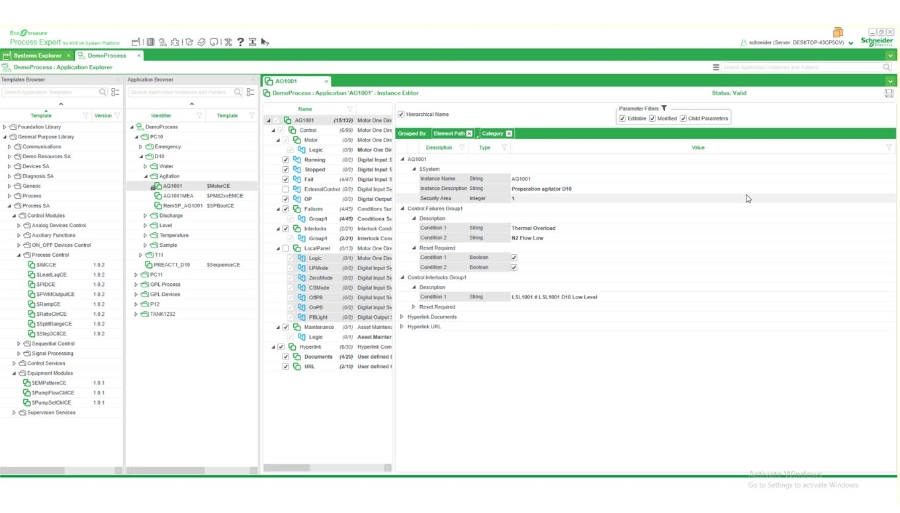

Integrated automation system• EcoStruxure Process Expert for AVEVA System Platform is an integrated automation system to manage the complete life cycle of a modern control system based on Modicon Controllers and AVEVA System Platform.• The Integrated Automation System enables users to achieve operational profitability from design engineering to meet the demands of modern-day production. It provides an asset-centric and object-oriented automation platform to deploy system-wide standards in a digital ecosystem.

General Information on EcoStruxure Process Expert for AVEVA System Platform

Highlights

Highlights

• A scalable, collaborative server/client architecture that allows multiple engineers to simultaneously configure an object-oriented automation system.• A single entry point of asset configuration• Automatic generation of the plant model• Automatic population of assets parameters• Access to the Unified Operation Center

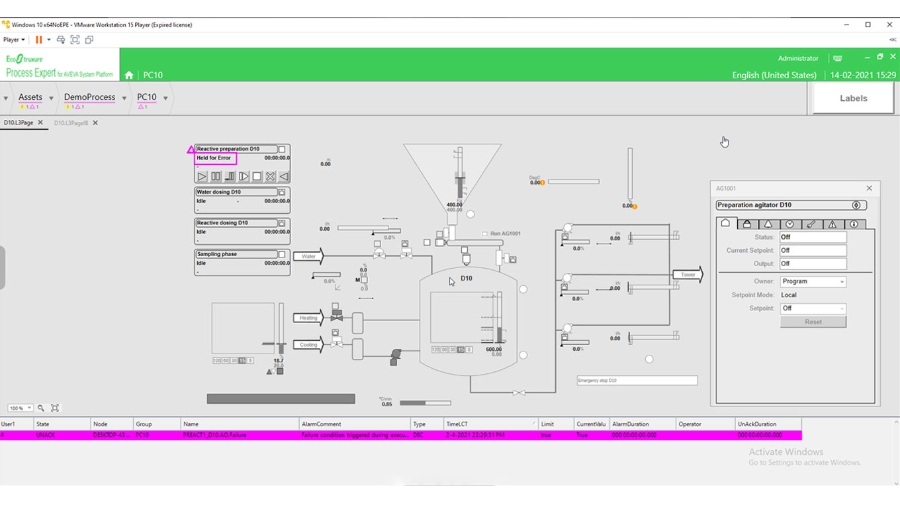

• Flexible, extensible, configurable, and customizable templates for general-purpose process applications.• The supervisory facets incorporate Situational Awareness concepts, advanced alarm management, and historical data management to boost plant operators' efficiency, delivering all the data and production insights to make timely and accurate business decisions.

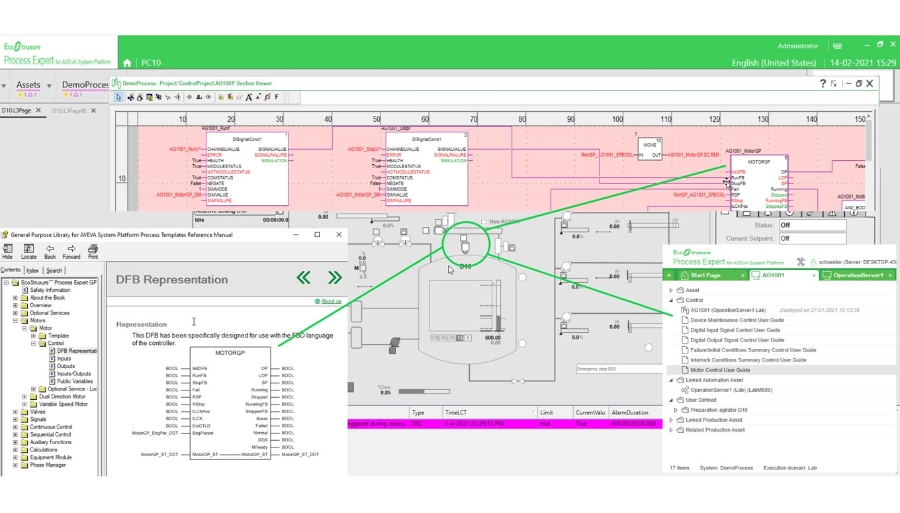

• Digitize your plant and empower plant workforce with smart global navigation.• Plant workforce can access in real-time contextualized plant asset data such as real-time control logic monitoring, maintenance procedures, asset documentation, asset management, etc to efficiently operate and maintain the plant.

Benefits of EcoStruxure Process Expert for AVEVA System Platform

Reduce engineering effort

To boost efficiency, and reduce engineering cost and time to market.

Improve operational profitability

With Situational Awareness tool to improve productivity.

Improve maintenance

With tools for faster fault resolution to move towards 100% uptime.

Improve plant performance

With the process automation system offering connectivity to business intelligence tools such as Historian or Batch for analysis and optimization.

EcoStruxure Process Expert for AVEVA System Platform features

EcoStruxure Process Expert for AVEVA System Platform features

• Object-oriented system for reuse of the design and increase engineering efficiency, as well as reduced time to market.• Ready to use system and segment libraries with a wide range of process automation templates.• Modular templates for enabling selection of desired services for each asset based on the process needs.• Multi-user engineering environment for scalable and flexible server/client architecture for concurrent engineering.• Bulk engineering tool with easy interface and edit capabilities using applications like Excel.• Automatic HMI application objects with multi-variant animated symbols for faster development of graphical pages.• Late binding with automation controllers with the flexibility to change easily.• Virtualization of server/client architecture for reduced hardware footprint.

• Central repository to store the configurations of the automation system for seamless sharing of information and easy maintenance.• Engineering traceability with built-in audit trail and progress indication for various actions performed in multi-user architecture.• Version control assures smooth mechanism for managing changes in automation assets.• Access control and transparent check-in/check-out mechanism ensures data integrity and secured multi-user engineering.• Embedded simulation capabilities that allow the simulation of the entire system which greatly reduces errors during the design phase.• Zero (0) programming, 100% configuration for reduced engineering efforts and higher consistency.• TVDA - Tested Validated and Documented Architecture for optimized configuration and performance.

• System based on standards to meet project dynamics and compliant with the requirements of regulated industries.• Assured quality code with unique GenLock mechanism and in-built consistency check.• Traceability at engineering and operations assures high quality and profitability.• System documentation with the capability to add user documents for smooth operation and quick diagnostics or maintenance.

• Propagation of changes for higher consistency across the automation system.• Safe deployment of changes with zero downtime.• Hardware configuration changes without stop of process for online maintenance and extension of the plant.• Runtime Navigation Services (RTNS) for faster navigation, advanced diagnostics and data access in real-time for any device or equipment.