Discover PacDrive 3

Discover PacDrive 3

PacDrive 3 for an integrated system approach

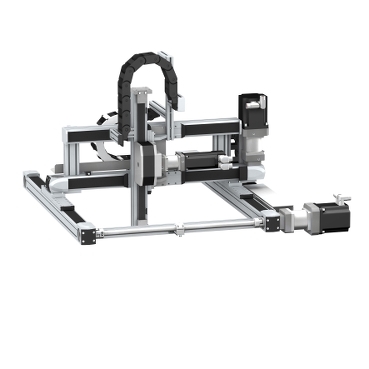

With its centralised system architecture, PacDrive 3 is the ideal solution for controlling a broad range of servo-driven production and packaging machines, as well as material handling equipment and robotics, using fully integrated, IEC 61131-3-compliant programme structures.

General information on PacDrive 3

Highlights

Highlights

For years, PacDrive control technology has allowed users to have synchronised multi-axial motion, PLC functionality, and robotic control on a single hardware platform. This open technology utilising international standards is aimed at reducing hardware and software complexity.

Benefits of PacDrive 3

Benefits of PacDrive 3

Improved efficiency

Minimise programming efforts and increase the software quality with modular programming concept with comprehensive application software libraries.

Motion simulation

Centralised calculation of all axis positions within the controller allows it to switch on the fly from real to virtual axes. Utilise motion testing/simulation without connecting drives or motors.

Easy device replacement

Electronic type plates and detailed communication for all servo drives/motors enable automatic parameterisation, firmware replication, and diagnosis.

Fast commissioning

Automatic Sercos scan after changing machine configuration/restart. The controller recognises all connected drives or motors and can activate or deactivate them automatically.

PacDrive 3 features

PacDrive 3 features

Facts about PacDrive 3

- Scalable automation platform and scalable controller performance from 0 to 130 servo drives and robot axes.

- Single controller solution for motion, PLC logic, and communication without additional hardware required.

- One programming tool for the complete machine, IEC 61131-3-compliant programming design.

- Software transferrable between platforms.

- Fully integrated Ethernet-based communication using Sercos for I/O, drive, and safe communication.

- An open system supporting other field busses as well as TCP/IP communication.

- Flexible multi-axis drive solutions; cabinet-based and servo integrated.

- EcoStruxure™ Machine Expert-based tools supporting the engineering process, including safety programming/parameterizing, commissioning, and diagnostics.

- Embedded safety approach with the safe logic controller, safe I/Os, safe drives, and safe communication.

- Robotic solutions (kinematic packages, including drives, electronics, and software).

Success stories

PacDrive 3 delta robots for food production with Sewtec automation

Building high-performance packaging systems for SOMIC