Flexible and sustainable machines and lines with integrated industrial robots

Industrial robots play a key role in the future of smart manufacturing and smart factories. Growing demand for robotics is driven by the desire to increase productivity, flexibility and quality, customise on-demand production, reduce costs, and time-to-market. As a strong digital transformation and advanced automation partner, we help machine builders, original equipment manufacturers (OEMs), integrators, and end users to implement end-to-end integrated multi-robotics solutions. EcoStruxure™ is an integrated and IoT-ready platform, including robotics, simulation, automation control, software, and digital services, enabling you to benefit from high payoff at every stage of the lifecycle and make the machines and production lines more flexible and sustainable.

Industrial Robotics powers the shift to smart manufacturing by improving productivity, flexibility, and quality. It helps machine builders, OEMs, integrators, and end users deploy connected multi-robot systems. With platforms like EcoStruxure™, Industrial Robotics enables efficient control, simulation, and digital services for sustainable, high-performance operations across industries.

Need to increase manufacturing production quality, consistency, flexibility, and efficiency while ensuring greater worker safety? Learn how robotics make manufacturing more efficient in the OMDIA paper.

Explore our integrated solutions for robotics

Easily choose your robotics solutions

Need help selecting the right robot for your application?

Use this simple selector to find the best fit for your needs.

Discover our products

Find the best integrated robotics applications

With just a few clicks in the Digi-Cat, you can quickly find all the components you need to build your integrated robotic solution.

Access our e-catalogue

Next-gen packaging machine flexibility for boosting productivity

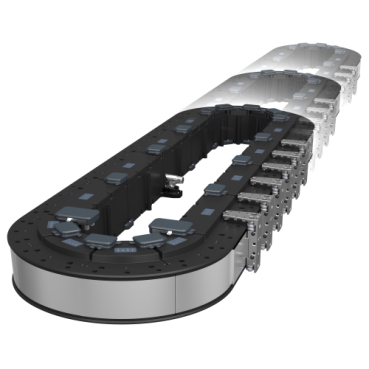

Learn how Lexium MC12 multi-carrier transport system coupled with digital twin technologies can increase product variations without increasing costs or time-to-market.

Access the interactive demo

Explore our latest insights on industrial robotics

Unilogo: Full speed ahead

Unilogo builds more flexible and sustainable high-speed filling lines using EcoStruxure robotic and digital twin solutions.

Explore moreAcma: Building flexible and sustainable packaging machines

Digital twin and robotic solutions help Acma build more flexible, modular, and compact automatic packaging machines — faster.

Find out moreLivetech: Unprecedented machine flexibility

Explore how Livetech, specialising in secondary packaging robotic applications in the food industry, achieved up to 40% cost savings and 50% faster changeover time by using Lexium MC12 multi carrier and robots.

Explore moreSewtec: Packaging solution for pet food producer

See how Sewtec helped its customer upgrade their existing production line to deliver a scalable end-of-line packaging solution that boosts flexibility and productivity.

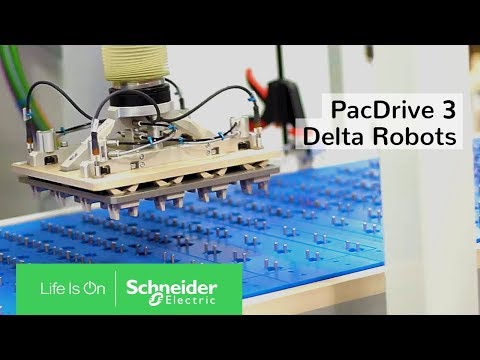

MG-Tech rises to the new challenges of the food industry

Find out how MG-Tech, the French leader in packaging machinery, uses PacDrive 3 and EcoStruxure solutions to rise to the flexibility and scalability challenges while optimising space by 30%.

Orion: More flexibility and faster changeovers

The innovative Lexium MC12 multi-carrier, coupled with digital twin technology, has transformed the way Japanese machine builder Orion Machinery designs and develops its automatic packaging machines.

Explore our complete portfolio of in-class, virtual, and online trainings to build your industrial robotic automation future with peace of mind.

Industries we serve

Machine Control IoT solutions

Industrial robots are indispensable in machinery segments, such as packaging, assembly, material working, and conveying, that require high endurance, volume, speed, and precision.

Discover nowFood and Beverage

In this segment, robotics is about offering a versatile and flexible solution. Industrial robotic automation parts must be designed in adherence to unique hygienic requirements.

Learn more

Life Sciences

With rising demand for new drugs, robotics support laboratory and life science industry processes through increased efficiencies, improved throughput times, and reduced costs.

Find out more

EV battery

The rapidly expanding electric vehicle (EV) market requires high-precision of batteries, a key application for robotics. Strong supply chains and robotics are critical success factors for battery cell production and recycling. Robotics help reduce costs, increase capacity in real-time, and boost productivity.

Read more

What are Schneider Electric solutions for industrial robotic automation?

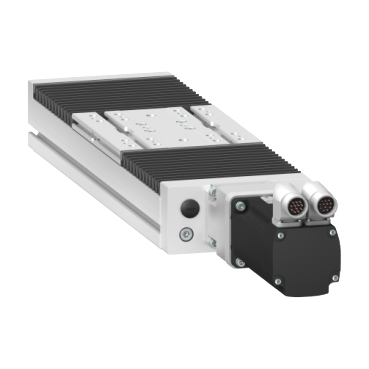

As a robust digital transformer and smart robotics and transport systems partner, we help machine builders, original equipment manufacturers (OEMs), integrators, and end users easily implement end-to-end integrated robotics solutions, answering the needs for mass customisation while reducing costs and time to market. Our Lexium line of smart industrial robots and transport systems enables real-time synchronisation, high-speed motion, as well as precise positioning and handling.

What are the benefits of implementing our industrial robotic automation solutions?

Implementing our industrial robotic solutions — digitally designed from concept to operation and maintenance and integrated into one machine control architecture — can help you benefit from a high payoff at every stage of the lifecycle. From reducing design and time-to-market by up to 50% to time savings in commissioning time by up to 60% and on corrective actions by up to 50%. EcoStruxure, our open, IoT-enabled architecture with a digital twin at the core, helps you simplify the integration of industrial robotics into the machine control solution to answer the challenges of smarter manufacturing, more flexible and sustainable while improving employee safety and welfare. Partnering with us also relies on our robotics experts and partners’ networks available worldwide.

How can we help you better understand the benefits of industrial robotic automation solutions?

Embracing industrial robotics automation solutions as a tool for sustainability is also a step toward a more sustainable future for the planet overall and for businesses in such sectors as machinery, food and beverage, life sciences, logistics and warehousing, battery manufacturing, and semiconductor. It enables us to provide a safer work environment, while ensuring sustainable outcomes, such as reducing energy consumption and waste, tracking, and lowering emissions for internal operations and smoother production. Learn more on our training platform.

What is Industrial Robotics?

Industrial Robotics uses automated machines and control systems to perform tasks like assembly, welding, and packaging. It enhances precision, speed, and consistency in manufacturing while reducing manual effort and improving overall production quality for growing industries worldwide.

How do Industrial Robotics systems work?

Industrial Robotics systems use sensors, controllers, and actuators to perform tasks. Sensors capture data, controllers process commands, and robots execute movements with accuracy. This coordinated workflow ensures efficient, repeatable operations across manufacturing environments.

What industries benefit the most from Industrial Robotics?

Industries such as automotive, electronics, food processing, pharmaceuticals, and logistics rely heavily on Industrial Robotics. These sectors gain improved accuracy, faster production, and safer operations, making robotics essential for high-volume and quality-driven work across global markets.

What are the main types of Industrial Robotics used today?

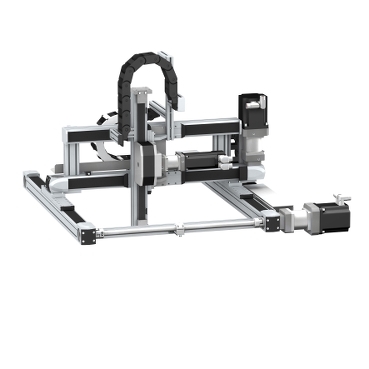

Common types of Industrial Robotics include articulated robots, Supervisory Control and Data Acquisition (SCARA), delta robots, Cartesian robots, and collaborative robots. Each type supports different tasks like assembly, material handling, inspection, and packaging with precision and flexibility.

How do Industrial Robotics improve efficiency and productivity?

Industrial Robotics boosts efficiency by performing tasks faster, reducing errors, and maintaining consistent output. Robots support continuous operation, minimize downtime, and help businesses meet production goals while improving overall workflow performance and long-term reliability.

Are Industrial Robotics suitable for small and medium-sized businesses?

Yes, Industrial Robotics is suitable for small and medium-sized businesses due to affordable collaborative robots, modular systems, and scalable automation. These solutions improve productivity, reduce labor strain, and support growth without requiring large investments or complex setups.

What role does AI play in Industrial Robotics?

AI enhances Industrial Robotics by enabling robots to learn, adapt, and make decisions. It improves vision systems, predictive maintenance, path planning, and quality checks, allowing robots to handle complex tasks with greater accuracy and intelligence across fast-changing industrial environments.

What safety standards apply to Industrial Robotics in manufacturing?

Industrial robotics follows strict global safety standards that guide robot design, operation, and human interaction. These standards help ensure worker safety, reduce operational risks, and maintain controlled robot behavior in manufacturing environments across various industries.

How do companies integrate Industrial Robotics into existing operations?

Companies integrate Industrial Robotics by assessing workflows, selecting suitable robots, updating control systems, and training staff. Robots are added gradually to ensure compatibility, improve efficiency, and support smoother transitions in production processes while strengthening operations.

What are the maintenance requirements for Industrial Robotics?

Industrial Robotics requires routine inspections, lubrication, software updates, and calibration. Monitoring wear, sensors, and controllers help prevent failures. Regular maintenance ensures long equipment life, reliable performance, and reduced downtime while supporting safer industrial operations.

.svg)