The mechanical and plant engineering industry is facing major problems due to a shortage of skilled workers. Existing employees often have to perform tasks that could be completed much more quickly today. There is considerable potential for improvement, particularly in the wiring of motor protection switches and contactors. Conventional screw-type connection technology is time-consuming. While spring loaded and push-in terminals offer faster solutions, they are only partially suitable for untrained personnel and robots, are more difficult to handle, and are not suitable for all cable types.

With over 100 years of experience in motor protection, we present the new generation of TeSys Deca with snap-in technology! This enables tool-free connection in just one second per conductor, accelerating the connection process by up to 96 percent. The robust spring terminals remain secure even under vibration and require no retightening. The snap-in terminals provide acoustic, haptic and visual feedback through a distinct clicking sound when the conductor is correctly engaged.

The groundbreaking snap-in connection technology enables significant time savings in wiring. It enables both unskilled workers and robots to create error-free connections. Tool-free, one-handed assembly, clear feedback, and zero maintenance greatly simplify the wiring process. This allows systems to be commissioned quickly, efficiently, and safely.

TeSys Snap-In | Product Overview

Our motor management approach delivers products and solutions for machine, process, and building applications. It enables you to design and select the best fit of the offer portfolio to achieve sustainable optimization in CapEx and OpEx.TeSys Power GV2

Motor protection switch protection against overload, short circuit and phase failure to prevent overheating and damage

Order motor protection switchTeSys Control D

Power contactors for switching and interrupting large currents in the electrical industry

Order power contactorsTeSys D

Auxiliary contactors For automation and control technology for switching small currents or control signals

Order auxiliary contactor

Incredibly good reasons for TeSys Deca Snap-In

Wiring made easy – In a snap!

The innovative snap-in connection technology enables time-saving, tool-free installation that's intuitive and incredibly easy to use. This not only reduces assembly time but also significantly reduces the risk of injury. The system's flexibility proves to be a real asset, especially in hard-toreach areas. You also benefit from lower costs by eliminating the need for tool purchases and maintenance. Efficient, safe, and sustainable – perfectly tailored to your needs.

Delivery condition

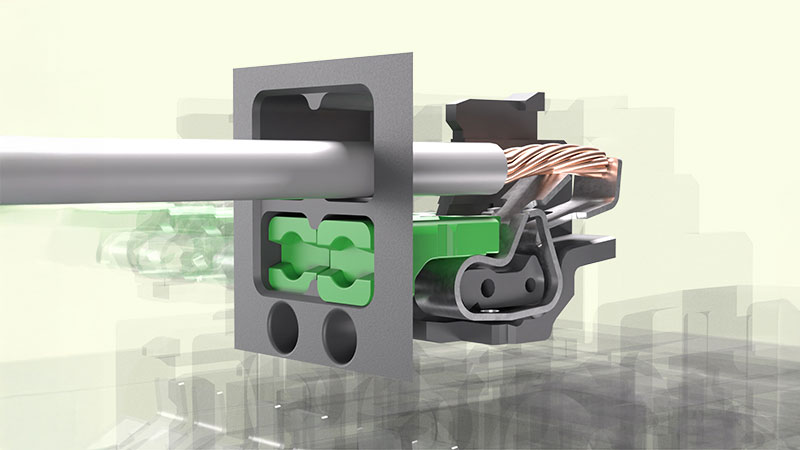

The device is delivered with a preloaded spring. The position of the push button indicates the switching state of the preloaded clamping point.

wiring

Inserting the stripped wire into the terminal point is easy and safe, without any further preparation required

clamping

When the wire touches the terminal's ground contact, the spring in the clamping point releases and snaps onto the terminal. This changes the position of the trigger, accompanied by a distinct "click."

Unwiring

First, reset all buttons using a 2.5-3.5 mm screwdriver. Then, you can easily pull the wires out of the terminals with one hand.

Snap-In | |||||

Push-In | — | — | — | ||

spring balancer | — | — | — | ||

screw | — | — | — | — | — |

Finally get to the point faster!

The simple wiring method not only allows laypeople or automated systems to effortlessly connect the wires to the terminals, but also significantly reduces the time required. Snap-in technology allows a conductor to be connected in just two seconds. This represents a time savings of 96 percent compared to approximately 30 seconds with screw connections. Snap-in wiring is also up to 88 percent faster than spring terminals and push-in systems.

WEF = Wire-End Ferrule

Connection times in comparisonSnap-In | 1 second | Not necessary — 11 s | 1 s without WEF — 1 s with WEF | 2-12 s without WEF - 2-12 with WEF |

Push-In | 1 second | Not necessary — 11 s | 6 s without WEF — 2 s with WEF | 7-18 s without WEF — 3-14 s with WEF |

spring balancer | 1 second | Not necessary — 11 s | 6 s without WEF — 2 s with WEF | 7-18 s without WEF — 3-14 s with WEF |

screw | 1 second | 11 seconds | 18 seconds | 30 seconds |

An outstanding feature of the new snap-in connection technology is its complete maintenance-free nature. The springs used exert such strong pressure that the contacts do not loosen even under strong shocks or vibrations. This makes the particularly robust terminals ideal for control cabinets in demanding environments or in hard-to-reach locations for electrical distribution. Typical applications include rail transport, construction equipment, and challenging industrial environments. Users can rely on an electrical connection that prevents faulty wiring even under extreme conditions. This avoids lengthy aintenance work or even operational downtime due to loose connections.

The innovative snap-in terminal block is specifically designed for an automated future and is therefore "ready-to-robot." A collaborative robot—such as the Lexium Cobot from Schneider Electric—can perform the necessary wiring tasks. The robot arm simply needs to insert the wire into the appropriate opening. Through clear audio-visual feedback during insertion, a robot with appropriate sensors can ensure optimal contact closure.

Do you want to automate your processes? Our experts are happy to assist you with your project inquiry.