What is a distributed control system (DCS)?

What is a distributed control system (DCS)?

A distributed control system (DCS) is the brain controlling the processes in energy-intensive, process-heavy facilities. This digital automated industrial control system achieves this by using geographically distributed control loops throughout a plant or machine. A modern distributed control system will increase safety and efficiency and is vital in making operations profitable in the coming decades.

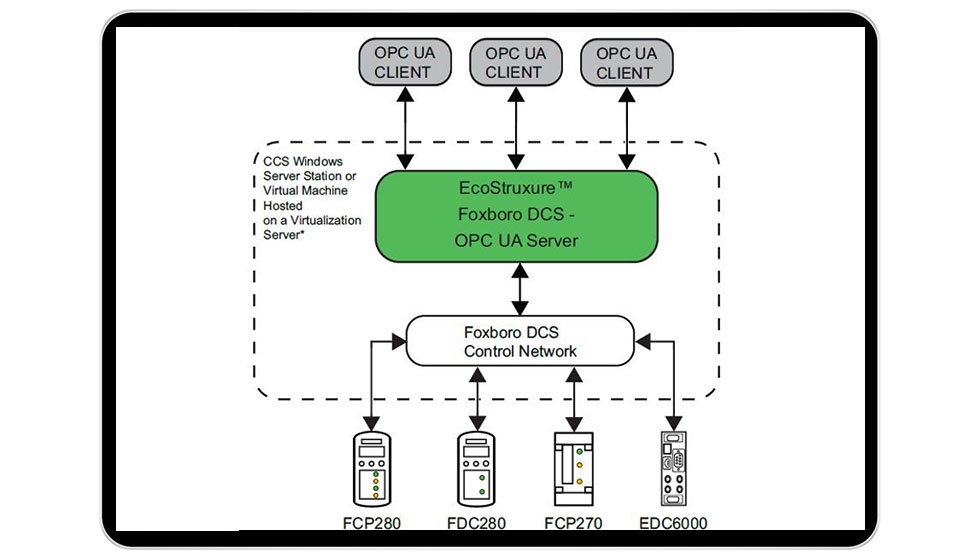

EcoStruxure Foxboro DCS - distributed control system

EcoStruxure™ Foxboro™ DCS is an innovative family of fault-tolerant, highly available control components, that consolidate critical information and elevate staff capabilities to ensure flawless, continuous plant operation, and support the digital transformation of processes.Upgrading to Foxboro DCS offers a resilient DCS solution to reduce risk and achieve key business development initiatives.

Take control of industrial digital transformation

63% of current control systems are only somewhat equipped to support their company’s digital transformation. We commissioned Omdia to survey 250 global business leaders to capture essential perspectives and specific challenges they face on their journey toward digital transformation.

Migrate your DCS

As your Distributed Control System (DCS) ages, the risk of production interruptions or plant shutdowns increases. Save time with a less complex migration process and future-proof your operations.

Benefits of EcoStruxure™ Foxboro DCS

Benefits of EcoStruxure™ Foxboro DCS

Features

Features

Know more about EcoStruxure™ Foxboro DCS

- Packed with state-of-the-art OT technologies like dynamic SAMA, engineer anywhere and control anywhere capabilities, visualisation and situation-awareness functionalities, and the latest IT technologies in mobility, cloud and analytics.

- Architecturally optimised for smart design and flexible engineering reducing capital and operating expenses, protecting operational integrity while enhancing decision-making, problem resolution, and workflow.

- Provides a powerful platform to turn your industrial automation into a universal automation of your business, driving measurable operational profitability safely. When coupled with open, IEC 61499 standards-based solutions, like EcoStruxure Automation Expert and our other offers, the Foxboro DCS provides customers with even more choice and flexibility, so they can:

- Leverage and adopt advancements in technology and hardware much faster, and not the 18 months to two years it takes in the current model.

- Adopt technology that IT has been leveraging for years.

- And more quickly address emerging and new critical challenges.

EcoStruxure Foxboro DCS technology platforms

EcoStruxure Foxboro DCS technology platforms

Field Device Controller 280

The Field Device Controller 280 provides control and Ethernet/serial interfaces between single or dual-ported PLCs, drives, and other distributed control devices and EcoStruxure™ Foxboro DCS. The FDC 280 optimises the integration of control devices such as PLCs and increases flexibility — while minimising system engineering, footprint, and cost.Features of Field Device Controller 280 includes:

- Liquid crystal display (LCD) — shows letterbug and real-time roles and statuses.

- Support for multiple networked connections — Ethernet, RS232, RS485, RS422.

- 50% reduction in footprint and wiring compared with CP plus FDSI solution.

- Downloadable and upgradable protocol drivers, online.

- Drivers include:

- Serial (RS232; RS422; RS485):

- Modbus RTU.

- Ethernet:

- Modbus TCP Client.

- TSAA (Triconex™ System Access).

- OPC UA Client.

- Ethernet/IP Scanner.

- Serial (RS232; RS422; RS485):

Field Control Processor 280

Field Control Processor 280 dependably performs regulatory, logic, timing and sequential control, as well as data acquisition, alarm detection and notification. Their patented, fault-tolerant design offers the highest availability plus nonstop operation.The FCP280 coexists with — and migrates from — the earliest generations of Foxboro automation platform hardware. The FCP280 provides twice the capacity and three times the performance of previous controllers — improving performance and cost-effectiveness in even the most demanding applications.Features of Field Control Processor 280 includes

- Ensured cybersecurity — ISA EDSA certified

- Online image upgrade (OLUG)- Accepts four PIO channels (four separate HDLC fieldbuses)

- Plant-wide data integration

- Rated for Class G3 harsh environments

- CE-certified for field mounting in enclosures

Electrodynamic Controller

EcoStruxure™ Electrodynamic Controller (EDAC), cornerstone of the power and process control system, is the first to market with advanced data integration, time synchronisation, and programming for controlling and monitoring electrical distribution from the distributed control system. With a focus on cybersecurity and high availability, it helps reduce CAPEX through less reliance on hardwired solutions and lower engineering costs, while also minimising OPEX by enhancing recovery from or avoiding unplanned downtime.

Simulated Control Processor

Our simulated control processor (SCP) is a virtual simulation of Foxboro control processors CP270 and CP280, combined with DYNSIM® dynamic modelling capability. SCP is built on the block algorithms and communication infrastructure of EcoStruxure™ Foxboro DCS and I/A Series® process automation.All operational and engineering applications, processes, and equipment that run with Foxboro control systems run the same way with SCP software.Features of the Simulated Control Processor include

- Functionality identical to a Foxboro CP

- One-to-one SCP-to-real-CP Relationship

- Support for virtualisation and cloud environments

- Small hardware footprint

- Support for all standard Foxboro configuration tools

- Can be mixed with standard CPs during process automation system (PAS) factory acceptance test (FAT)

- Easy bulk configuration of tie-back models

- Support for direct links to other control software, including EcoStruxure Triconex Safety Systems, Rockwell, Emerson, Siemens, GE, and Yokogawa; as well as support for many other PLC, SIS, PAS, and third-party simulation software offerings

Applications

Energies and chemicals

Explore moreMining, minerals and metals

Explore moreWater

Explore moreLife sciences

Explore more

Additional resources

Additional resources

How can distributed control systems catapult automation into the future?

Know moreThe value of reimagining process automation

Know more

Process automation learning services

Explore our digital and in-person courses, specially designed to ensure the technical skills of your automation workforce are future-ready. Or request a custom learning solution to address your unique training needs.

Learn more on Foxboro DCS

Learn more on Foxboro DCS