Lavazza makes an impact: Key results

Increased production capacity

Uninterrupted processes with 24/7 support

Greater agility and flexibility to satisfy consumer demands

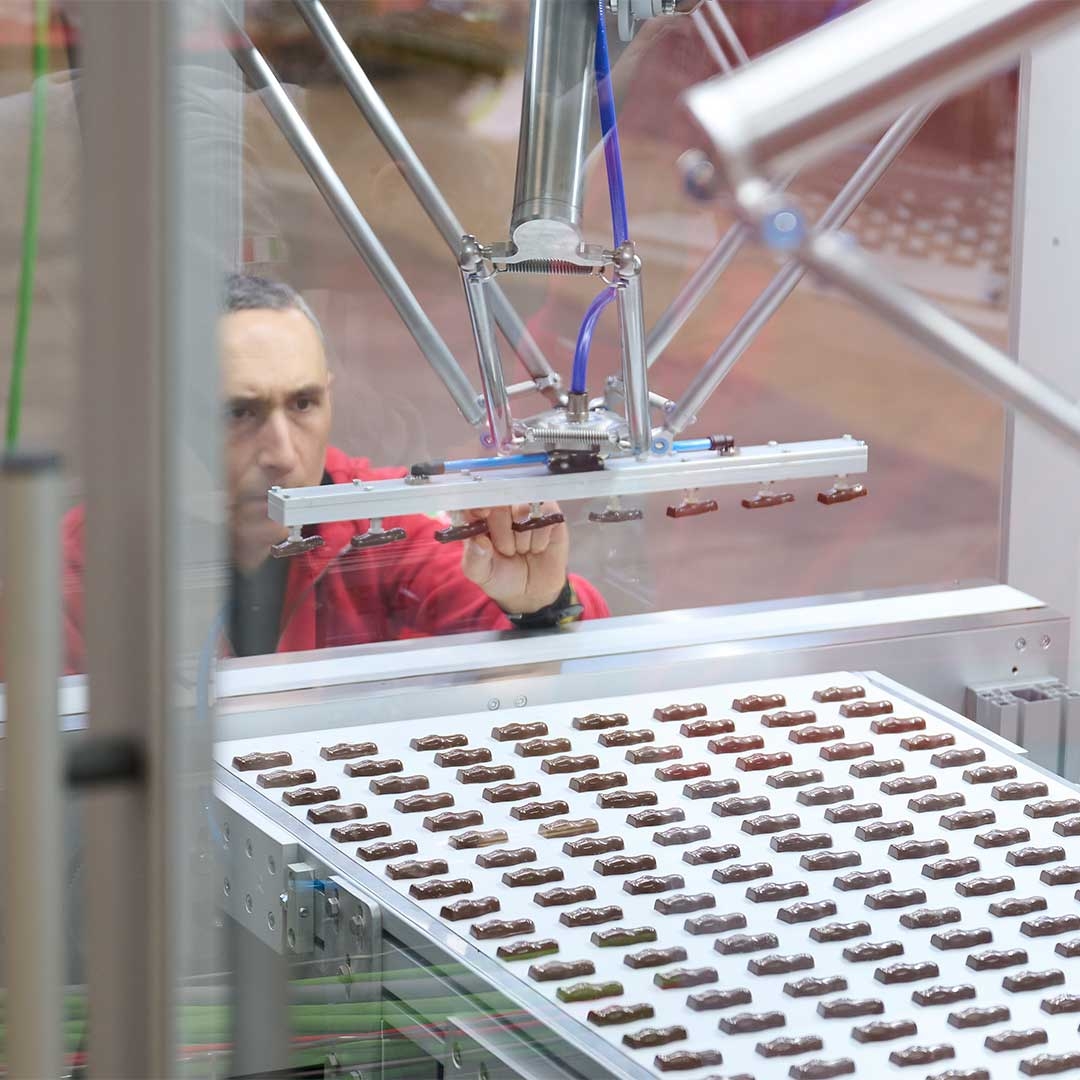

Lavazza, one of the most recognised names in the premium coffee sector, has been collaborating with Schneider Electric for more than two decades. We have guided it through a digital transformation with leading automation solutions and the availability of around-the-clock service support. Lavazza’s robust and agile production lines are now primed to seamlessly accommodate ever-changing market demands so coffee lovers the world over can enjoy their favourite drinks.

Solutions used by Lavazza

- AVEVA™ System Platform

-

AVEVA™ System Platform

AVEVA™ System Platform Modicon Edge Control -

Modicon Edge Control

Modicon Edge Control Altivar variable speed drives -

Altivar variable speed drives

Altivar variable speed drives