Roll over image to zoom in

+ 5

1 videos

XB4BA61

Cap/operator or lens colour:

Contacts type and composition:

Marking:

Environmental Data

Total lifecycle Carbon footprint

1

Use Better

Packaging made with recycled cardboard

Yes

Use Longer

Product repair index

A

Use Again

Take-back

No

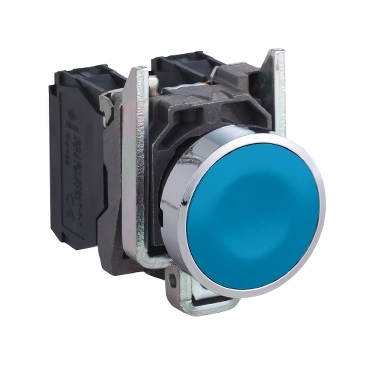

This Harmony XB4 modular blue push button operates with a spring return / impulse mechanism. It has a metal bezel. This push button provides an ergonomic interface for controlling your machines. It is easily installed into standard 22mm diameter panel cut-outs and connected to control circuits with classic screw-clamp connections. Its schematic is clearly distinguishable thanks to clear colors and markings, minimizing errors during initial wiring and later maintenance operations. It is impact resistant, dust resistant, water resistant and vibration resistant thanks to its IP66 / IP67 / IP69 / IP69K, making it ideal for operation in harsh environments.

| Range of product | Harmony XB4 |

|---|---|

| Device short name | XB4 |

| Product or component type | Push-button |

| Bezel material | Chromium plated metal |

| Fixing collar material | Zamak |

| Mounting diameter | 22.5 mm |

| Sale per indivisible quantity | 1 |

| Shape of signaling unit head | Round |

| Type of operator | spring return |

| Operator profile | Blue flush, unmarked |

| Head type | Standard |

| Contacts type and composition | 1 NO |

| Contact operation | Slow-break |

| Connections - terminals | Screw clamp terminals, <= 2 x 1.5 mm² with cable end conforming to IEC 60947-1 Screw clamp terminals, 1 x 0.22...2 x 2.5 mm² without cable end conforming to IEC 60947-1 |

| Height | 47 mm |

|---|---|

| Width | 30 mm |

| Depth | 52 mm |

| Terminals description ISO n°1 | (13-14)NO |

| Net weight | 0.08 kg |

| Resistance to high pressure washer | 7000000 Pa at 55 °C, distance : 0.1 m |

| Contacts usage | Standard contacts |

| Positive opening | Without |

| Operating travel | 2.6 mm (NO changing electrical state) 4.3 mm (total travel) |

| Operating force | 3.8 N NO changing electrical state |

| Mechanical durability | 10000000 cycles |

| Tightening torque | 0.8…1.2 N.m conforming to IEC 60947-1 |

| Shape of screw head | Cross compatible with Philips no 1 screwdriver Cross compatible with pozidriv No 1 screwdriver Slotted compatible with flat Ø 4 mm screwdriver Slotted compatible with flat Ø 5.5 mm screwdriver |

| Contacts material | Silver alloy (Ag/Ni) |

| Short-circuit protection | 10 A cartridge fuse type gG conforming to IEC 60947-5-1 |

| [Ith] conventional free air thermal current | 10 A conforming to IEC 60947-5-1 |

| [Ui] rated insulation voltage | 600 V (pollution degree 3) conforming to IEC 60947-1 |

| [Uimp] rated impulse withstand voltage | 6 kV conforming to IEC 60947-1 |

| [Ie] rated operational current | 3 A at 240 V, AC-15, A600 conforming to IEC 60947-5-1 6 A at 120 V, AC-15, A600 conforming to IEC 60947-5-1 0.1 A at 600 V, DC-13, Q600 conforming to IEC 60947-5-1 0.27 A at 250 V, DC-13, Q600 conforming to IEC 60947-5-1 0.55 A at 125 V, DC-13, Q600 conforming to IEC 60947-5-1 1.2 A at 600 V, AC-15, A600 conforming to IEC 60947-5-1 |

| Electrical durability | 1000000 cycles, AC-15, 2 A at 230 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C 1000000 cycles, AC-15, 3 A at 120 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C 1000000 cycles, AC-15, 4 A at 24 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C 1000000 cycles, DC-13, 0.2 A at 110 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C 1000000 cycles, DC-13, 0.5 A at 24 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C |

| Electrical reliability | Λ < 10exp(-6) at 5 V and 1 mA in clean environment conforming to IEC 60947-5-4 Λ < 10exp(-8) at 17 V and 5 mA in clean environment conforming to IEC 60947-5-4 |

| Device presentation | Complete product |

| Protective treatment | TH |

|---|---|

| Ambient air temperature for storage | -40…70 °C |

| Ambient air temperature for operation | -40…70 °C |

| Overvoltage category | Class I conforming to IEC 60536 |

| IP degree of protection | IP66 conforming to IEC 60529 IP67 IP69 IP69K |

| NEMA degree of protection | NEMA 13 NEMA 4X |

| IK degree of protection | IK06 conforming to IEC 50102 |

| Standards | JIS C8201-5-1 IEC 60947-5-1 IEC 60947-1 UL 508 IEC 60947-5-4 IEC 60947-5-5 CSA C22.2 No 14 JIS C8201-1 |

| Product certifications | CSA LROS (Lloyds register of shipping) BV UL listed DNV |

| Vibration resistance | 5 gn (f= 2…500 Hz) conforming to IEC 60068-2-6 |

| Shock resistance | 30 gn (duration = 18 ms) for half sine wave acceleration conforming to IEC 60068-2-27 50 gn (duration = 11 ms) for half sine wave acceleration conforming to IEC 60068-2-27 |

| Unit Type of Package 1 | PCE |

|---|---|

| Number of Units in Package 1 | 1 |

| Package 1 Height | 8.800 cm |

| Package 1 Width | 3.400 cm |

| Package 1 Length | 5.400 cm |

| Package 1 Weight | 79.000 g |

| Unit Type of Package 2 | S03 |

| Number of Units in Package 2 | 150 |

| Package 2 Height | 30.000 cm |

| Package 2 Width | 30.000 cm |

| Package 2 Length | 40.000 cm |

| Package 2 Weight | 12.480 kg |

| Unit Type of Package 3 | P06 |

| Number of Units in Package 3 | 1200 |

| Package 3 Height | 75.000 cm |

| Package 3 Width | 60.000 cm |

| Package 3 Length | 80.000 cm |

| Package 3 Weight | 108.340 kg |

| Warranty | 12 months |

|---|

Schneider Electric aims to achieve Net Zero status by 2050 through supply chain partnerships, lower impact materials, and circularity via our ongoing “Use Better, Use Longer, Use Again” campaign to extend product lifetimes and recyclability.

Total lifecycle Carbon footprint

1

Environmental Disclosure

Use Better

Packaging made with recycled cardboard

Yes

Packaging without single use plastic

Yes

Pro-active compliance (Product out of EU RoHS legal scope)

REACh Regulation

Use Longer

Product repair index

A

Use Again

End of life manual availability

Take-back

No

WEEE Label

The product must be disposed on European Union markets following specific waste collection and never end up in rubbish bins

Dimensions

e : clamping thickness: 1 to 6 mm / 0.04 to 0.24 in.

(1) Additional row of contacts or double contact.

Panel Cut-out for Pushbuttons, Switches and Pilot Lights (Finished Holes, Ready for Installation)

Connection by Screw Clamp Terminals or Plug-in Connectors or on Printed Circuit Board | Connection by Faston Connectors |

|

|

(1) Diameter on finished panel or support (2) 40 mm min. / 1.57 in. min. (3) 30 mm min. / 1.18 in. min. (4) Ø 22.5 mm / 0.89 in. recommended (Ø 22.3 mm 0+0.4 / 0.88 in. 0+0.016) (5) 45 mm min. / 1.78 in. min. (6) 32 mm min. / 1.26 in. min. | |

Items usually bought together

Need more information? Check our technical FAQs!

Easily find answers to the most frequently asked questions.