ZB5AZ101

Contacts type and composition:

| Range of product | Harmony XB5 |

|---|---|

| Product or component type | Complete body/contact assembly |

| Device short name | ZB5 |

| Fixing collar material | Plastic |

| Sale per indivisible quantity | 1 |

| Head type | Standard |

| Contacts type and composition | 1 NO |

| Contact operation | Slow-break |

| Contact block type | Single |

| Connections - terminals | Screw clamp terminals, <= 2 x 1.5 mm² with cable end conforming to IEC 60947-1 Screw clamp terminals, >= 1 x 0.22 mm² without cable end conforming to IEC 60947-1 |

| CAD overall width | 30 mm |

|---|---|

| CAD overall height | 42 mm |

| CAD overall depth | 32 mm |

| Terminals description ISO n°1 | (13-14)NO |

| Net weight | 0.021 kg |

| Device composition | Fixing collar Body |

| Contacts usage | Standard contacts |

| Positive opening | Without |

| Operating travel | 2.6 mm (NO changing electrical state) 4.3 mm (total travel) |

| Operating force | 2.3 N NO changing electrical state |

| Mechanical durability | 10000000 cycles |

| Tightening torque | 0.8…1.2 N.m conforming to IEC 60947-1 |

| Shape of screw head | Cross compatible with Philips no 1 screwdriver Cross compatible with pozidriv No 1 screwdriver Slotted compatible with flat Ø 4 mm screwdriver Slotted compatible with flat Ø 5.5 mm screwdriver |

| Contacts material | Silver alloy (Ag/Ni) |

| Short-circuit protection | 10 A cartridge fuse type gG conforming to IEC 60947-5-1 |

| [Ith] conventional free air thermal current | 10 A conforming to IEC 60947-5-1 |

| [Ui] rated insulation voltage | 600 V (pollution degree 3) conforming to IEC 60947-1 |

| [Uimp] rated impulse withstand voltage | 6 kV conforming to IEC 60947-1 |

| [Ie] rated operational current | 3 A at 240 V, AC-15, A600 conforming to IEC 60947-5-1 6 A at 120 V, AC-15, A600 conforming to IEC 60947-5-1 0.1 A at 600 V, DC-13, Q600 conforming to IEC 60947-5-1 0.27 A at 250 V, DC-13, Q600 conforming to IEC 60947-5-1 0.55 A at 125 V, DC-13, Q600 conforming to IEC 60947-5-1 1.2 A at 600 V, AC-15, A600 conforming to IEC 60947-5-1 |

| Electrical durability | 1000000 cycles, AC-15, 2 A at 230 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C 1000000 cycles, AC-15, 3 A at 120 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C 1000000 cycles, AC-15, 4 A at 24 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C 1000000 cycles, DC-13, 0.2 A at 110 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C 1000000 cycles, DC-13, 0.5 A at 24 V, operating rate <3600 cyc/h, load factor: 0.5 conforming to IEC 60947-5-1 appendix C |

| Electrical reliability | Λ < 10exp(-6) at 5 V, 1 mA in clean environment conforming to IEC 60947-5-4 Λ < 10exp(-8) at 17 V, 5 mA in clean environment conforming to IEC 60947-5-4 |

| Device presentation | Basic sub-assemblies |

| Protective treatment | TH |

|---|---|

| Ambient air temperature for storage | -40…70 °C |

| Ambient air temperature for operation | -40…70 °C |

| IP degree of protection | IP20 conforming to IEC 60529 |

| Standards | UL 508 IEC 60947-5-1 CSA C22.2 No 14 IEC 60947-5-4 IEC 60947-1 JIS C8201-5-1 JIS C8201-1 |

| Product certifications | BV UL CSA DNV LROS (Lloyds register of shipping) |

| Vibration resistance | 5 gn (f= 2…500 Hz) conforming to IEC 60068-2-6 |

| Shock resistance | 30 gn (duration = 18 ms) for half sine wave acceleration conforming to IEC 60068-2-27 50 gn (duration = 11 ms) for half sine wave acceleration conforming to IEC 60068-2-27 |

| Unit Type of Package 1 | PCE |

|---|---|

| Number of Units in Package 1 | 1 |

| Package 1 Height | 4.500 cm |

| Package 1 Width | 3.400 cm |

| Package 1 Length | 5.400 cm |

| Package 1 Weight | 20.000 g |

| Unit Type of Package 2 | S03 |

| Number of Units in Package 2 | 300 |

| Package 2 Height | 30.000 cm |

| Package 2 Width | 30.000 cm |

| Package 2 Length | 40.000 cm |

| Package 2 Weight | 6.530 kg |

| Unit Type of Package 3 | P06 |

| Number of Units in Package 3 | 2400 |

| Package 3 Height | 75.000 cm |

| Package 3 Width | 60.000 cm |

| Package 3 Length | 80.000 cm |

| Package 3 Weight | 62.684 kg |

| Warranty | 12 months |

|---|

(1) Diameter on finished panel or support

(2) For selector switches and Emergency stop buttons, use of an anti-rotation plate type ZB5AZ902 is recommended.

(3) Ø22.5 mm recommended (Ø22.3 0+0.4) / Ø0.89 in. recommended (Ø0.88 in. 0+0.016)

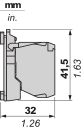

Connections | a in mm | a in in. | b in mm | b in in. |

|---|---|---|---|---|

By screw clamp terminals or plug-in connector | 40 | 1.57 | 30 | 1.18 |

By Faston connectors | 45 | 1.77 | 32 | 1.26 |

On printed circuit board | 30 | 1.18 | 30 | 1.18 |

(1) Diameter on finished panel or support

(2) For selector switches and Emergency stop buttons, use of an anti-rotation plate type ZB5AZ902 is recommended.

(3) Ø22.5 mm recommended (Ø22.3 0+0.4) / Ø0.89 in. recommended (Ø0.88 in. 0+0.016)

Items usually bought together

Need more information? Check our technical FAQs!

Easily find answers to the most frequently asked questions.